1. Introduction

Labelflash

technology was recently introduced by Yamaha Corporation and Fuji Photo Film

Co. This technology promotes the ability to burn images directly onto a

specialised dye layer on the disc label side, with the same laser used for data recording.

This technology allows consumers to personalise and customise their DVDs with

photos, text and graphics, replacing traditional sticker and marker labeling.

Labelflash

technology was recently introduced by Yamaha Corporation and Fuji Photo Film

Co. This technology promotes the ability to burn images directly onto a

specialised dye layer on the disc label side, with the same laser used for data recording.

This technology allows consumers to personalise and customise their DVDs with

photos, text and graphics, replacing traditional sticker and marker labeling.

Labelflash technology allows a consumer to burn pictures and/or write titles

on the label side of the DVD discs, specially developed for the Labelflash system

with DVD writers with the Labelflash function. There is no need for printers and

consumables for printing. To obtain high resolution and high contrast pictures

in blue and silver colour, a consumer only needs to turn the disc upside down

and insert it into the drive again, after burning the data. The technology burns

the image 0.6mm deep into the media in as little as five minutes, creating

a more stable and permanent image than traditional printable media that uses

the

top layer of a disc for labeling.

| General Specifications of Labelflash System |

| Laser wave length |

655nm |

| NA |

0.65 |

| Picture-burning time |

5min (Fast mode) - 20min (High Quality mode) |

| General Specifications of Labelflash Disc |

| Depth of the picture-burning layer |

0.6mm from the disc surface |

| Dye for the picture-burning layer |

Organic Dye |

| Picture-burning area (radius) |

25mm - 58mm |

A look at the past

The technology marries the unique Yamaha DiscT@2 ("Tattoo") technology

for picture burning on the data side with the photochemical expertise of Fuji

Photo Film, which is a leading company in technologies for optical media.

Back in 2002, YAMAHA had developed the DiscT@2

technology, allowing laser printing on a CD. It was a technology on which Labelflash

is based. In that case however, users had to sacrifice some of their data space

on the CD,

since printing took place on the data side of the disc and usually

on

the outer region of the CD. In other words, the DiscT@2 labels were "burned"

on the same side as the data, and not on the top side (label side)

of the disc.

Following on the DiscT@2 concept, LabelFlash is quite straightforward to use.

The image (label) consists of grayscale information with x-y coordinate values. The LabelFlash-capable application converts the x-y

coordinate information to polar coordinate information. The application then

sends the

data with polar coordinates to the LabelFlash drive, which in our case is the

NEC

ND-4551A.

LabelFlash printing can be theoretically done on any DVD-/+R media, by simply placing the disc right side up

in the tray and printing the label on the data side as was done with DiscT@2. Of course, that would require that the burner's firmware

support printing on non-LabelFlash discs. In our tests, we used

the NEC ND-4551A with firmware v1.07 installed and the drive managed to print

on DVD-R and DVD+R media, but not on CD-R media (not supported).

How it works

Usually, a burning application will supply a DVD recorder with raw digital

data, to which the recorder's hardware adds header and error correction information

and then converts it to the so-called eight to sixteen (EFM+) modulated

patterns. These are the little chunks of data that get written to the disc.

The modulated patterns for DVD writing vary from a minimum value

to a maximum value. A combination of

these patterns,

is

used for writing to DVD-R and DVD+R. The result is that the burned area looks

darker than the unused area. LabelFlash takes things further and breaks free

from

the limitations imposed by normal

modulated patterns. This allows for more flexibility in how the laser burns

onto DVD recordable media,

making the formation of visible images possible.

2. The Drive, the Media and the Software

- The Drive

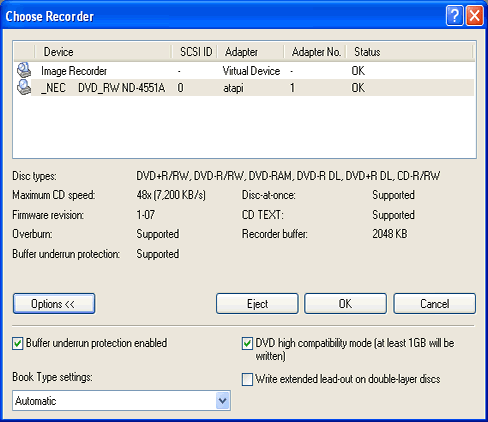

In order to test this technology, we used the NEC

ND-4551A, flashed with firmware version 1.07, which is the only one that supports the LabelFlash Technology.

As we said previously, you can use Labelflash as well

on the data side of any standard DVD-R or DVD +R media, by burning the label

on the outer area of the data side of the disc, or on the whole area if you

don't burn any actual data on it.

|

| The main chipset of the drive... |

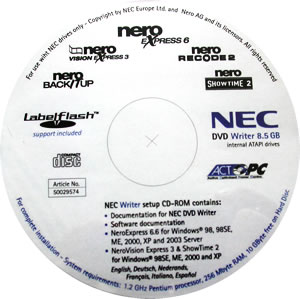

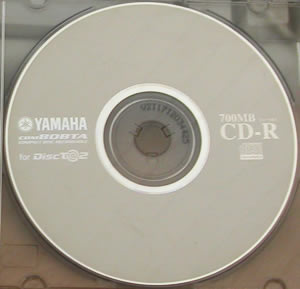

- The media

The media we used for our test was made by Fujifilm. It was a DVD-R certified for 16X recording. The depth of the picture-burning layer is 0.6mm from the disc surface while the Dye for the picture-burning layer is the Organic Dye. The Picture-burning area (radius) is 25mm - 58mm.

The media we used for our test was made by Fujifilm. It was a DVD-R certified for 16X recording. The depth of the picture-burning layer is 0.6mm from the disc surface while the Dye for the picture-burning layer is the Organic Dye. The Picture-burning area (radius) is 25mm - 58mm.

- The Software

Nero in cooperation with Yamaha made a version that supports the LabelFlash

Technology but currently this version is for bundle with OEM customers. The

Nero 6.6.1.3 bundles in the retail package of the ND-4551A recorder and supports

LabelFlash. It is not sure whether Nero

will add this

feature

will be in

Nero 7.

BHA has also announced support for the LabalFlash in its OEM version of the

Bs software, bundled with a LabelFlash burner under the Japanese I-O Data brand.

The familiar interface of Nero Burning Rom will guide you through the simple

steps in order to "LabelFlash" your media.

3. The Tests

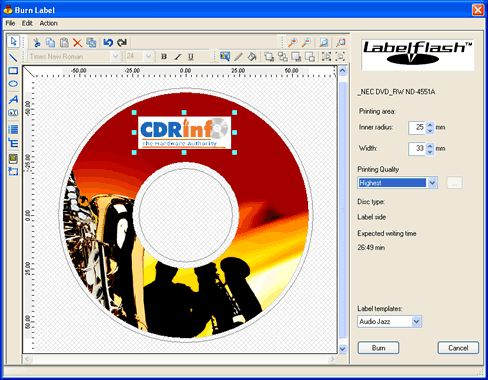

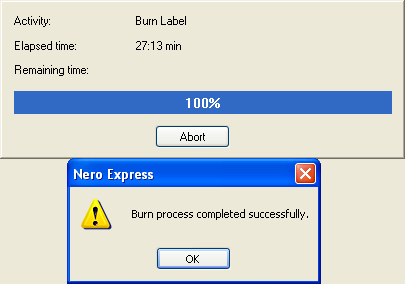

We ran Nero Express and clicked on the "More" button in order to see the extra features. By selecting the "Burn Label" button, you enter the label maker screen.

We made a print project and selected to print it at the highest available printing quality. There are three available qualities you can use to print your project. For each one, there is an estimated time, reported by the software. We selected the highest...

There are also some extra settings regarding the print quality that you can change:

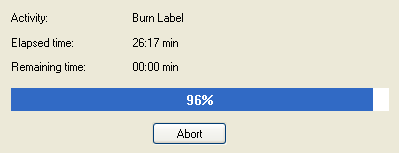

As soon as you are ready, press "Burn" to start the printing procedure.

When the printing process is finished, you'll get an appropriate message. In our case, the time needed was 27:13 minutes, while the program's estimated time at the start was 26:49 minutes, a negligible difference. What was the result? Check below:

Despite our attempts to provide as realistic photos as possible, the effect is nowhere near as impressive as seeing the actual disk itself. The disks have a very shiny surface, due to the protection surface on the dye, which cannot be portrayed in our two images.

The labels have a consistent look while the protective layer on the disc provides some degree of protection and durability.

We also experimented with non-LabelFlash certified DVD-R and DVD+R media to see what the results would be. We printed an image on the data side of the disc that took up the entire surface area on the disk. The resulting label was barely visible (the contrast between light and dark areas is minimal), and in fact, you can only discern an image if you look very hard at the disk and without reflections. All in all, if you didn't know that an image had been printed, you wouldn't have noticed it. Despite this, we took our experiment a step further and tried to write actual data on the disc. Lo and behold, Nero correctly identified the media and proceeded to burn our project (a DVD movie), completing successfully. There was no noticeable difference in the label quality other than perhaps that it was a shade darker.

The real test though was yet to come. Was this disc a working disc? Would our drive read it? Alas, no. We tried playing the DVD with Power DVD but to no avail. Interestingly enough though, with Windows Explorer, we could explore the disk's contents and list the video files that are normally present on a DVD movie compilation. Double clicking on a VOB file, in many cases actually played for a fraction of a second and then stopped. With the merging of what the label's image and then the data had burned on the disk, it appeared like a corrupt or badly damaged disk.

Not that we were terribly disappointed because the label image quality was hardly worth the effort in the first place. But why wasn't the disc rejected by Nero when we burned our data on it, after we had printed the image? What we believe happened, is that when data is written on a DVD, it has to follow a particular format, including IDs, error correction, etc, much in the same way a hard disc is formatted by an operating system before any data can be written to it or read from it. Now, remembering that the image and data are written on the same side of the disk using the same laser, obviously, the image we printed did not follow the DVD formatting rules and most probably, as far as Nero was concerned, looked like blank DVD media.

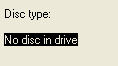

As a side note, we should say that you cannot use Lightscribe

media with the NEC drive, even if you place it upside down in the drive's

tray.

Current

firmware

for

the

ND-4551A

does not recognize any LightScribe discs. In addition, the ND-4551A could not

label on our old, DiscT@2 CD-R discs since CD-Rs are not supported by LabelFlash.

Just a thought :)

We tried with our NEC ND-4551A, to burn CD-R media but we got the following

message:

| DiscT@2 Media |

LightScribe Media |

|

|

- Final thoughts

Printing with LabelFlash is certainly interesting, but as in the

case of the competing LightScribe labeling technology, the time needed to

label a disc is substantial. We expect that there will be wider support from software and media, as well as a more consistent behavior from LabelFlash drives through updates in their respective firmware. The sleek and glossy finish of a LabelFlash

label is definitely a plus, making it an attractive way to promote your

DVD-ROM presentations with potential customers. The availability as well as the price

for LabelFlash media are also factors that will decide its future. FujiFilm

will commercialize its 16x DVD-R discs later this month, and Ritek also plans

to release LabelFlash media in Q1 2006.