1. Introduction

The primary concern when using optical storage media to

store data, is to ensure that the result will be

a readable disc, over a very long period of time.

Readability then, depends on the reading drive, which is influenced by the

resultant writing quality produced on the disc, which is in turn

directly related to the recorder used for burning

and the optical medium itself.

The primary concern when using optical storage media to

store data, is to ensure that the result will be

a readable disc, over a very long period of time.

Readability then, depends on the reading drive, which is influenced by the

resultant writing quality produced on the disc, which is in turn

directly related to the recorder used for burning

and the optical medium itself.

The Optical Storage industry has defined specific parameters

that reflect the quality of a recorded disc. These

are actual measurements of electric signals that

represent the overall condition of a disc and, when

looked at as a whole, provide a complete picture of the recording quality. These signals provide information about

the physical condition of a disc and the integrity

of the digital data, as they are stored on the disc

and retrieved by the player.

Quality testing has been practiced for decades now,

first for CD and later for DVD media. Currently, with

the High-Definition formats already available on the

market, there is a further and growing need for accurate testing. Moreover, the fact that the next-generation

formats are squeezing even more data onto 12cm

media using various techniques, makes it easy to

understand why measuring the quality of the

recorded data is more complicated when compared to CD and

DVD.

In the following pages, we present some writing

quality measurements of BD-R (Blu-Ray Recordable)

and BD-RE (Blu-Ray Re-Rewritable) media. The discs

were burned with some of the most popular Blu-Ray recorders for

PCs, currently available on the market. In

cooperation with DaTARIUS, the leader in quality

optimization, measurements and evaluation of optical

storage media, CDRInfo presents a brief explanation

of the basic signals related to the quality of a

Blu-Ray disc, and of course, the first real-life

measurements on sample discs.

In the first pages, we tried to summarize the physical characteristics of the Blu-Ray disc format, the basics of the data encoding and error correction used, as well as an explanation of the basic signals that are essential for the evaluation of the writing quality of a Blu-Ray disc. Moving on, we provide information about the testing procedure, and of course the results.

At this point, we should mention that some discs were measured a second time. After initial measurements, a number of discs produced uncharacteristically poor results and we were keen to find out why. As we have done on similar occasions in the past when testing DVD media, we decided to run a second pass to confirm the results. Before doing the second pass, a random selection of discs was taken and cleaned using air spray and special tissues. The results after this procedure are quite revealing as will be seen in the ensuing pages.

2. Specs, Modulation, Error Correction On Blu-Ray

In order to make the Blu-Ray measurements more comprehensible, we summarize here the basic characteristics of

the Blu-ray format. The table below, shows the main

parameters of a Recordable Blu-ray Disc. To maximize

capacity and performance, the main optical system

parameters of the Blu-ray Recordable Disc include a

laser diode wavelength of 405 nm and an

objective lens NA of 0.85. Additionally, the

current maximum user data transfer rate is 144 Mbps

(4X). The channel modulation is 17PP and the

recording area can be either on-groove or in-groove.

Modulation Methods

Modulation methods are the means of encoding the

source data to the channel bit data recording on the

disc.

The modulation scheme used for Blu-Ray Disc is 17

Parity preserve-Prohibit repeated minimum run-length

transition (17PP). Parity preserve (P) refers to the

method of ensuring the DC content in the data is

zero. 17 refers to the minimum and maximum allowable

run length limits (RLL) for data features (e.g. the

marks/spaces, pits/lands) on the disc. So for BD we

have a minimum data feature size of 2T and a maximum

data feature size of 8T for the data (compared with

3T and 11T for the data features on DVD). Due to sync

frames, feature lengths of 9T can occur.

Modulation of the data occurs after the data has

been previously passed through the Error Correction Code

(ECC) encoder.

Data Recovery Methods: Partial Response - Maximum

Likelihood (PRML)

For CD and DVD, the method for data detection was

based on a zero crossing point method, using a

conventional slicer. Basically, when the analogue

signal (output from the optical pick-up) crosses a

reference level, it indicates a binary transition.

This method has its limitations, notably when the

feature size (smallest pit/land) is less than the

spot size, the modulation of the light is relatively

small (the smaller the pit/spot size ratio the smaller

the modulation). Thus, the conventional slicer can

create data with non-exact mark/space lengths -

otherwise known as jitter, and when this jitter

becomes greater than 0.5 of a clock cycle, it becomes

a bit error.

For BD, the minimum spot radius ratios are 0.88 and

0.85 of the ratio of DVD. This reduced resolution

(low modulation of light by 2T pits) means that it

is much more difficult to have effective data

detection using a conventional slicer. Boosting the

high frequency part of the signal has limited effect

because this also increases the InterSymbol

Interference (ISI), which is where adjacent pits and

lands interfere with each other. This is mainly a

problem with the shortest run lengths, particularly

those that are smaller than the spot size.

Hence for BD, the Partial Response- Maximum

likelihood (PRML) method is used for recovering the

data from the signal.

Partial Response (PR) equalization is used to limit

the effects of ISI, and then a sequence of bits is

evaluated to define the most likely sequence of

bits, based upon known allowed sequences. This is

the Maximum Likelihood (ML) detection and uses a

Viterbi algorithm to determine the ML sequence.

The Blu-Ray disc is more sensitive to burst errors

compared to the DVD system. Therefore, the error

correction system of Blu-Ray disc should be able to

cope well with long burst errors, rather with single

(random) errors.

The maximum number of errors that can be corrected depends on the number of parity symbols added. For each two parity symbols added, one error can be corrected. But Blu-Ray uses a more efficient approach to correct the burst errors. It uses a burst indicator mechanism that can detect bursts of errors before the correction starts. The advantage of this method is actually the prior knowledge of the error locations on the decoding process.

These burst indicator used in the Blu-Ray format is called picket code. The pickets are columns that are inserted in between columns of the main data at regular intervals. The main data is protected by a Reed Solomon code, while the pickets are protected by a second independent Reed Solomon code. When decoding (reading), first the picket columns are corrected. The correction information can be used to estimate the location of possible burst errors in the main data.

A BluRay Disc Error Correction Block (ECC Block) can store 64 Kilobytes of user data. This data is protected by the Long Distance Code (LDC) which has 304 code words with 216 information symbols and 32 parity symbols giving a code word of length 248. These code words are interleaved two by two in the vertical direction such that a block if 152 bytes x 469 bytes is formed as shown in the picture above.

A Blu-Ray Disc ECC block contains 4 equally spaced picket columns. The left most picket is formed by the sync pattern at the start of each row. If the sync pattern was not detected properly, that can be an indication for a burst error similar to the knowledge that a symbol of a picket column had to be corrected. The other three pickets are protected by the so-called Burst Indicator Subcode (BIS). The BIS code words are interleaved into three columns of 496 bytes each. Both LDC and BIS codes are decoded by the Reed Solomon decoder.

Reference: BD-ROM Physical Specifications

3. Basic Blu-Ray Disc Writing Quality Signals

The measurement issues for the next generation formats, go substantially beyond simply working with smaller features. The coding concepts, the relationships between measurements and playability are all unique.

Let's start with the basic signals related to the measurements for the Blu-Ray disc, as they are provided by the Blu-Ray specifications.

References:

BD Specifications for Read-Only Disc

Part 1 Physical Specifications

DaTARIUS BD Signal Guide v1.0

Blu-Ray Signals |

| |

Abbreviation |

Specification |

| Mechanical parameters |

| Focus Error 1 - Axial residual error |

FE1 |

≤ 45 nm |

Focus Error 2 - The rms noise of axial

residual error |

FE2 |

≤ 75 μmpp |

| RADIAL1 - Radial residual error |

RADIAL1 |

≤ 9 nm |

RADIAL2 – The rms noise of radial residual

error |

RADIAL2 |

≤ 6.4 nm BD SL

≤ 9.2 nm BD DL |

| Optical Parameters |

| I8H– Reflectivity in recorded tracks |

BD R8h-rth |

Min 35 %

Max 70 % |

| BD R8h-rth |

Min 12 %

Max 28 % |

| Track pitch |

Tpwa - TRP averaged over the Wide Pitch area |

0.350 ±0.003 μm |

| Tpna - Track pitch averaged over the Normal Pitch area |

0.320 ±0.003 μm |

| Operating Signals |

| 8T peak to peak modulation |

I8/I8H |

≥ 0.40 |

| 3T peak to peak modulation |

I3/I8 |

≥ 0.25 |

| Resolution I2/I8 equalized |

I2/I8 |

≥ 0.09 BD SL

≥ 0.09 BD DL |

| 8T modulation variation within one revolution |

I8HRv |

≤ 0.15 |

| Reflectivity modulation |

R8M |

Min 0.20

Max 0.70 |

BD SL |

Min 0.07

Max 0.28 |

BD DL |

| Asymmetry |

Asym |

Min 0.10

Max 0.15 |

| Leading edge jitter applying Limit Equalizer |

JRLi |

≤6.5 % |

| Trailing edge jitter applying Limit Equalizer |

JFli |

≤6.5 % |

| Radial Push Pull |

RPP |

Min 0.10

Max 0.35 |

| Track crossing signal |

TCS |

≥ 0.10 |

Differential Phase Detection – signal

amplitude |

DPDAMp |

Min 0.28

Max 0.62 |

Differential Phase Detection – signal

amplitude |

DPDAsy |

≤ 0.20 |

| Digital errors |

| Burst Error Count |

BEC |

In each physical cluster

BEC: the number of burst error with a length ≥ 40 bytes shall be less than 8 |

| Burst Error Length |

BEL |

In each physical cluster

BEL: the sum of all burst error length shall be equal or below 600 bytes |

| Symbol Error Rate |

SER/SERk |

|

| Random Symbol Error Rate |

RSER/RSERk |

≤ 2.0 * 10-4 |

Below is a brief explanation of the basic signals related to the BD quality measurements. These signals are the RSER, BEC,

R8H,

I8/I8H,

RADIAL2,

JFLi and

JRLi.

Digital Errors

For BD, signals related to digital errors are Random Symbol Error Rate (RSER), Burst Error Max, and Max total length of burst errors.

- RSER / RSERk– Random Symbol Error Rate

The Random Symbol Error Rate is defined as the Symbol Error Rate where all erroneous bytes contained in burst errors of which the length is ≥ 40 bytes are excluded from counting in the numerator as well in the denominator of the SER calculation.

The RSER value is calculated over 10,000 LDC Blocks. We should remind here that Long Distance Code (LDC) is included to protect the data. For more information read the previous page of this article.

Such errors can be caused by all optical defects that interfere with the normal

data read-out procedure (scratches, dots, black spots, bubbles, etc). Local

defects can cause the data contents to deteriorate. Others causes can be jitter

problems, stamper defects or a bad HF signal.

A byte error is when one or more bits (inside a byte) have a wrong value (as

detected by the error correction/detection circuits).

A burst error is a sequence of bytes in which there are not more than two

bytes between any two erroneous bytes. In order to determine the burst errors,

the bytes should be ordered in the same sequence as they are recorded on the

disc. The length of the burst is defined as the total number of bytes counted

from the first erroneous byte that is separated by at least three correct bytes

from the last succeeding erroneous byte.

The number of erroneous bytes in a burst is defined as the actual number of bytes in that burst that are not correct.

As in the case of RSER, such errors can be caused by all optical defects that interfere with the normal

data read-out procedure (scratches, dots, black spots, bubbles, etc).

Operation signals

I8H– Reflectivity in recorded tracks

The reflectivity parameter is the measure of the fraction of the light returning

from recorded layer in the information zone. It should include also

transmission through the cover layer. There are two types of discs foreseen:

higher reflectivity and lower reflectivity type.

Measuring conditions are specified. There are two preferential methods:

- collimated (parallel) beam method

- focused beam method

The focused method is used in players together with a reference disc of known

reflectivity value. The method is relative, yet it allows to eliminate the light

from parasitic reflectance's inside the disc as well as the light coming from the

front surface of the cover layer as well.

In the collimated method "total" reflectance is measured, and a calculation is

needed to determine the reflectance from the information layer. For this

method a very good reference disc (birefringence-free), with glass cover layer,

and golden reflective layer should be chosen.

Reflection is basically defined by the reflective layer. In most cases during the manufacturing process of Blu-Ray media, out-of spec

reflectivity means correction on the sputtering process (reflective layer

application). In some case this can be also connected with wrong dimensions

of the pits in the information area, or scattering of light on the surface of the

cover layer.

I8/I8H – 8T peak to peak modulation

In the reading process of a BD disc, the HF signal is obtained by summing the currents of the four elements of the photo detector. Below you can see an illustration of an HF signal.

8T Modulation shall be calculated according to the formula:

The value of I8/I8H modulation reveals information about the shape of the

pits, and subsequently of the quality of the replication process. A value lower

than the limit will lead to higher error rates and jitter.

Jitter on Blu-Ray

Assessing the quality of HD DVD and BD discs introduces new approaches to those accepted for DVD and CD and we look here at jitter, the most commonly understood quality metric.

Jitter, the difference between the idealized run lengths (pit and lands) and the actual detected run lengths, has been used in CD and DVD as a primary metric for determining the quality of the replicated disc.

When using a PRML approach, it has not been able to link regular (as used in CD and DVD) jitter directly to the quality of the replicated disc.

BD uses a different approach. In BD, a limit equalizer is employed upon the signal. This is simply another method of boosting the signal of the smallest features (2T pit and land). The advantage of the limit equalizer, compared with the conventional equalizer used for DVD, is that it can boost the signal of the smallest features without increasing the InterSymbol

Interference (ISI). After the signal has been processed through the limit equalizer, jitter measured in a conventional manner, as with DVD.

According to the Blu-Ray specifications, two signals have been defined for jitter measurements:

JRLi – Leading edge jitter applying Limit Equalizer

JFLi – Trailing edge jitter applying Limit Equalizer

Both leading and trailing edge jitters should be measured in each track with

the use of circuit corresponding to the following drawing. These

jitters are data-to-clock jitters measured with the Limit Equalizer set

appropriately to Channel bit length.

The jitter value expresses the distribution of rising or falling edge positions for

all the pits on a disc. In other words, jitter is the standard deviation of the

falling and rising edge of the digitized and equalized HF signals in respect to

the PLL clock.

The limits in jitter are the same for the leading as for the trailing edge of the

pits. However, there are small differences in the specifications of jitter for

dual layer discs. Higher jitter is in layer 1 is allowed when it is measured

together with I2 pits ( ≤ 8.5%). Without the I2 the limiting value of the jitters

are always the same ( ≤ 6.5%).

Jitters indicate accuracy in the definition of pits on a discs, and is likely to be

a influenced by the moulding process. Further reasons be an overly low HF

signal, due to low reflectivity of the reflective layer. If these process steps are

ruled our then the stamper, and possibly even the mastering process, must be

checked.

Servo &Tracking parameters

RADIAL1 – Radial residual error

The parameter, similarly to Focus Error, imposes limits on movements of the

head due to residual radial tracking error to 9 nm (for frequencies below 1.8

kHz). Spikes in the residual radial tracking error signal due to local defects,

such as dust and scratches, are excluded.

For dual layer discs the value of 13 nm is allowed.

The parameter protects the head from losing a track during reading due to any

extreme displacement of the track in a radial direction. This means that for

frequencies below 1.8 kHz the maximum local acceleration of the tracks in the

radial direction will not exceed 1.5 m/s².

For dual layer discs the value of 2.2 m/s² is allowed.

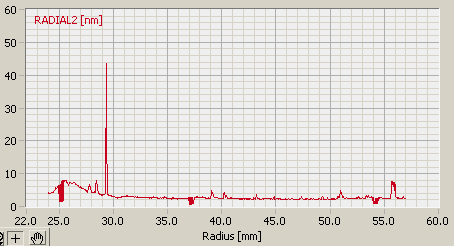

RADIAL2 – The rms noise of radial residual error

This is related to rms (root mean square): in other words the average value of

the RADIAL1 signal. The value should be lower than 6.4 nm, when measured

in the frequency band 1.8 kHz to 10 kHz, with integration time of 20 ms, and

using the reference servo for axial tracking.

For Dual Layer discs the value 9.2 nm is allowed.

Leaving behind all the theoretical aspects related to the Blu-Ray measurements, in the following pages we present the writing quality measurements we have carried out, in cooperation with DaTARIUS.

4. Testing procedure - The DaTARIUS dataBANK

Testing Process

A combination of Blu-Ray burners and BD-R/RE media were used for this test. All discs were burned at the highest allowed speed using the "Create Disc" function of Nero's CDSpeed utility, which burns the disc with data to its full capacity.

In the table below, you can see all the available media and burners we used in this test.

| Media brand |

Media ID |

Media type |

Nominal capacity |

Writer |

Writing speed |

Memorex |

MEI (001) |

BD-R |

25 GB |

LG GBW-H10N vGL02 |

2X |

TDK |

TDKBLDRBA (000) |

BD-R |

25 GB |

4X |

Verbatim |

VERBATIMa (000) |

BD-R |

25 GB |

4X |

TDK |

TDKBLDWBA (000) |

BD-RE |

25 GB |

2X |

Verbatim |

VERBATIM0 (000) |

BD-RE |

25 GB |

2X |

Sony |

SONY (001) |

BD-RE |

25 GB |

2X |

TDK |

TDKBLDRBA (000) |

BD-R |

25GB |

Liteon LH-2B1S vAL05 |

2X |

Memorex |

MEI (001) |

BD-R |

25GB |

2X |

Verbatim |

VERBATIM0 (000) |

BD-RE |

25GB |

2X |

Sony |

SONY (001) |

BD-RE |

25GB |

2X |

TDK |

TDKBLDWBA (000) |

BD-RE |

25GB |

2X |

Verbatim |

VERBATIMa (000) |

BD-R |

25GB |

|

2X |

TDK |

TDKBLDRBA (000) |

BD-R |

25GB |

2X |

Verbatim |

VERBATIM0 (000) |

BD-RE |

25GB |

2X |

As was mentioned in the opening remarks in the first page of this article, we tested the discs in two passes, before and after cleaning.

PASS 1 - Disc tested straight from the box:

The discs were tested without undergoing any specific procedure before testing. Present were some dust particles and visible signs of handling, such as minor scratches and fingerprints.

PHASE 2 Disc professionally cleaned

We randomly selected some of the recorded discs and cleaned them using (professional) air spray and special tissues.

Below you can see a sample picture of a BD-R disc before and after cleaning:

Before cleaning :

After cleaning:

DaTARIUS DaTABANK

The BD-R and BD-RE measurements of this test were conducted with the DaTARIUS DaTABANK system. The DaTABANK is DaTARIUS' flagship product, a top-loading, modular design developed following years of research and customer feedback. This all-format analyzer, in expandable banks of four drives, utilizes the patented Quality Web visual method of presenting results.

The new DaTARIUS BD Analyzer driveCube adds Blu-ray Disc analysis to the flagship DaTABANK system. In keeping with the DaTARIUS ‘prepared for the future’ philosophy, the BD Analyzer driveCubes can be specified for new DaTABANK systems or hot-swapped into existing DaTABANKs, thus extending their capability to include BD.

Two versions of the BD recordable driveCube are available: the BDR Analyzer 1X (BDR A 1X) and the BDR Analyzer Stamper 1X. The BD A 1X is used to measure BD recordable (blank and recorded) discs, single and dual layer. The BDR A S1X is a modified version of the BDR A 1X to additionally enable stamper measurements with its unique adapter system. Both driveCubes can also perform measurements on pre-recorded discs and stampers.

The BD driveCube measurement portfolio includes HF, jitter, digital, servo and mechanical. These are essential for Blu-ray Disc producers and format developers to assess the quality of their Blu-ray Disc product. The BD driveCubes are built around the DaTARIUS universal driveCube platform with adherence to format requirements that results in a high degree of repeatability, reproducibility and reliability of measurements.

The user interface is consistent with existing DaTABANK DaTAVIEW and Quality Web analyzer displays. These flexible, user-friendly, and configurable displays deliver the required data in fast and easy to assimilate formats. DaTABANK can be used with a mix of BD, HD DVD and DVD driveCubes to offer comprehensive format analysis.

For additional information, visit the DaTARIUS website.

5. Measurements - LG GBW-H10N 2x & Memorex BD-R

Pass 1 : Discs out of the box

The Memorex BD-R disc was tested as is. It is very likely that dust particles and signs of handling such as minor scratches and fingerprints are present. Note, that no defects, scratches, fingerprints, etc., were caused on purpose, but were due (if present), to the normal handling of the disc during our burning and testing process.

| Blu-Ray burner |

LG GBW-H10N vGL02 |

| Disc |

Memorex BD-R 25GB |

|

| Media ID |

MEI (001) |

Writing speed |

|

- Measurements

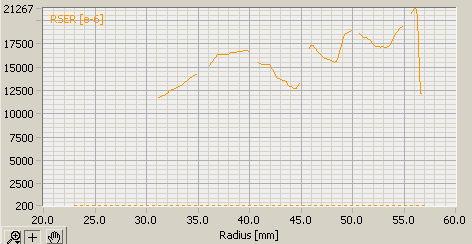

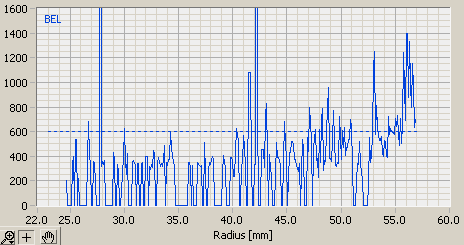

Digital errors (BEL, UNC, RSER)

Both Burst Error Length (BEL) and UNC (Uncorrectable) signals produced a spike at around the 47mm radius on the disc's surface. The specific issue is attributed to a possible defect on the disc surface. The average BEL is low, but there are points which rise to slightly higher than the specification limit for a Blu-Ray disc, which is less than 600 bytes.

The Random Error Symbol Rate (RSER) signal is beyond the limits for the complete area of the disc. The limit for this signal, which is calculated over 10,000 LDC blocks (see page with definitions), is set to 2 x 10-4. Such errors can be caused by optical defects that interfere with the data read-out procedure.

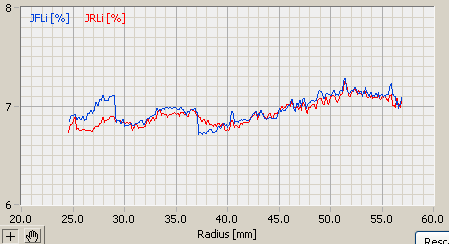

Jitter

Both JFli and JRli signals exceed the limits (6.5%).

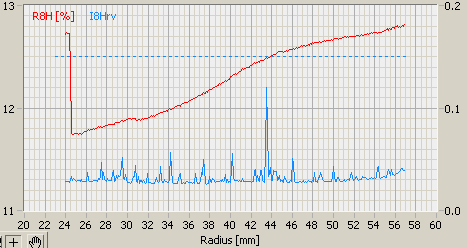

Reflectivity modulation

The I8/I8H signal actually shows information about the shape of the pits, and a value lower than the specified limit, could lead to digital errors and jitter.

Reflectivity

Reflectivity is generally good and stable over the disc .

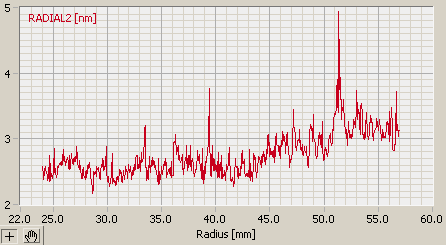

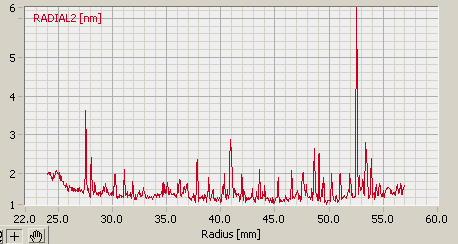

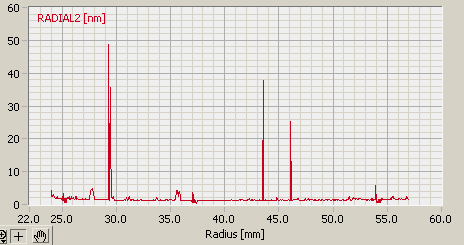

Servo & Tracking parameters - RADIAL2

As in the case with CD and DVD, RADIAL2 indicates whether the head of a reader loses track due to extreme displacement of the track in the radial direction. In our case, the signal stayed below the 6.4nm limit.

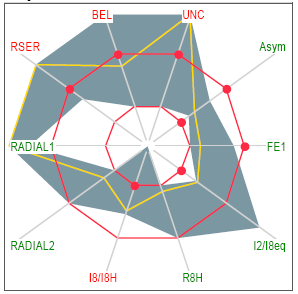

Summary of signals

The diagram on the left, could be very useful in providing a view of the condition of a disc at a glance.

Each signal indicated in red has exceeded the Blu-Ray Disc limits.

The summary of the signals indicate that the Burst Error Count (BEC) is low. However, the BE L signal is high, and the existence of uncorrectable digital errors ( UNC) could be puzzling. The high UNC signal was reported at a specific disc position, and it should be attributed to a local defect as we previously mentioned.

The specific disc was readable by Blu-Ray players.

Pass 2 : Disc cleaned

The specific disc was cleaned using (professional) air spray and special tissues. The disc was measured again, and the results are given below.

Digital errors

All signals

Cleaning the disc surface completely changed the picture of the quality of the disc. The maximum BEL signal fell from 5148 to 849, while the Uncorrectable errors dramatically decreased to just 8. The disc was readable.

The results underline the importance of keeping your Blu-Ray discs in perfect condition, away from dust and defect free. The nature of the Blu-Ray Disc format (NA 0.85) makes the read-out process a very delicate procedure, and the existence of any kind of particles on the disc's surface could make your disc unreliable.

Rest of the measurements:

Jitter - JFli, JRLi |

Reflectivity - I8/I8H |

|

|

Reflectivity Modulation R8H, R8Hrv |

RADIAL 2 |

|

|

6. Measurements - LG GBW-H10N 4x & TDK BD-R

Pass 1 : Disc out of the box

The disc was tested without undergoing any specific processing before testing. Present were some dust particles and handling defects such as minor scratches and fingerprints.

| Blu-Ray burner |

LG GBW-H10N vGL02 |

| Disc |

TDK BD-R 25GB |

|

| Media ID |

TDKBLDRBA (000) |

Writing speed |

4x CLV |

The specific disc was burned at 4X CLV.

- Measurements

Digital errors

BEL exceeded the limits in many cases, although no uncorrectable errors were reported, despite the 4x CLV burning speed.

RSER is increased over the complete data area, as we can see in the graph below.

Jitter

Reflectivity modulation

Reflectivity

Servo & Tracking parameters - RADIAL2

Although the spikes in the radial tracking error should be attributed to local defects on the disc surface, the peak in the signal's level at the beginning of the disc, reveals continuous tracking movements of the head in order to follow the data track. At the same area on the disc, high RSER and BEL were reported.

All signals

Despite the existence of digital errors, the specific disc was readable. The BEC was within specifications, and no UNC errors were reported.

7. Measurements - LG GBW-H10N 4x & Verbatim BD-R

Pass 1 : Disc out of the box

The disc was tested without undergoing any specific processing before testing. Present were some dust particles and handling defects such as minor scratches and fingerprints.

| Blu-Ray burner |

LG GBW-H10N vGL02 |

| Disc |

Verbatim BD-R 25GB |

|

| Media ID |

VERBATIMa (000) |

Writing speed |

|

- Measurements

Digital errors

Digital errors are generally low, with some spikes at specific spots. No UNC errors were reported.

RSER was slightly increased (max 276).

Jitter

Reflectivity Modulation

Reflectivity

Servo & Tracking parameters - RADIAL2

All signals

Reflectivity was generally adequate for the specific disc, and the RADIAL2 and BEL peaks should be attributed to local defects. No UNC errors occurred and the disc was readable.

8. Measurements - LG GBW-H10N 2x & TDK BD-RE

Pass 1 : Discs out of the box

The disc was tested without undergoing any specific processing before testing. Present were some dust particles and handling defects such as minor scratches and fingerprints.

| Blu-Ray burner |

LG GBW-H10N vGL02 |

| Disc |

TDK BD-RE 25GB |

|

| Media ID |

TDKBLDWBA (000) |

Writing speed |

|

- Measurements

Digital errors

Extremely BEL which results in high count of UNCs reported for this disc.

Jitter

Reflectivity modulation

Reflectivity

Servo & Tracking parameters - RADIAL2

All signals

9. Measurements - LG GBW-H10N 2x & Verbatim BD-RE

Pass 1 : Disc out of the box

The disc was tested without any specific handling before the testing. As a result, they presented some dust particles and handling effects such as minor scratches and fingerprints.

| Blu-Ray burner |

LG GBW-H10N vGL02 |

| Disc |

Verbatim BD-RE 25GB |

|

| Media ID |

VERBATIM0 (000) |

Writing speed |

|

- Measurements

Digital errors

Jitter

Reflectivity modulation

Reflectivity

Servo & Tracking parameters - RADIAL2

All signals

10. Measurements - LG GBW-H10N 2x & Sony BD-RE

Pass 1 : Disc out of the box

The disc was tested without undergoing any specific processing before testing. Present were some dust particles and handling defects such as minor scratches and fingerprints.

| Blu-Ray burner |

LG GBW-H10N vGL02 |

| Disc |

Sony BD-RE 25GB |

|

| Media ID |

SONY (001) |

Writing speed |

|

- Measurements

Digital errors

A very big spike in the UNC signal indicates possibly an abnormality on the disc surface.

Jitter

Reflectivity modulation

Reflectivity

Servo & Tracking parameters - RADIAL2

All signals

11. Measurements - LiteOn LH-2B1S 2x & Memorex BD-R

Phase 1 : Disc out of the box

The disc was tested without undergoing any specific processing before testing. Present were some dust particles and handling defects such as minor scratches and fingerprints.

| Blu-Ray burner |

LiteOn LH-2B1S vAL05 |

| Disc |

Memorex BD-R 25GB |

|

| Media ID |

MEI (001) |

Writing speed |

|

- Measurements

Digital errors

Jitter

Reflectivity modulation

Reflectivity

Servo & Tracking parameters - RADIAL2

All signals

Both the BEL and RSER signals gradually increased towards the end of the disc, although the UNC errors were reported earlier on.

12. Measurements - LiteOn LH-2B1S 2x & TDK BD-R

Phase 1 : Disc out of the box

The disc was tested without undergoing any specific processing before testing. Present were some dust particles and handling defects such as minor scratches and fingerprints.

| Blu-Ray burner |

LiteOn LH-2B1S vAL05 |

| Disc |

TDK BD-R 25GB

|

|

| Media ID |

TDKBLDWBA (000) |

Writing speed |

|

- Measurements

Digital errors

Jitter

Reflectivity modulation

Reflectivity

Servo & Tracking parameters - RADIAL2

All signals

13. Measurements - LiteOn LH-2B1S 2x & Verbatim BD-RE

Phase 1 : Disc out of the box

The disc was tested without any specific handling before the testing. As a result, they presented some dust particles and handling effects such as minor scratches and fingerprints.

| Blu-Ray burner |

Liteon LH-2B1S vAL05 |

| Disc |

Verbatim BD-RE 25GB |

|

| Media ID |

VERBATIM0 (000) |

Writing speed |

|

- Measurements

Digital errors

Jitter

Reflectivity modulation

Reflectivity

Servo & Tracking parameters - RADIAL2

All signals

14. Measurements - LiteOn LH-2B1S 2x & Sony BD-RE

Phase 1 : Disc out of the box

The disc was tested without undergoing any specific processing before testing. Present were some dust particles and handling defects such as minor scratches and fingerprints.

| Blu-Ray burner |

Liteon LH-2B1S vAL05 |

| Disc |

Sony BD-RE 25GB |

|

| Media ID |

SONY (001) |

Writing speed |

|

- Measurements

Digital errors

Jitter

Reflectivity modulation

Reflectivity

Servo & Tracking parameters - RADIAL2

All signals

15. Measurements - LiteOn LH-2B1S 2x & TDK BD-RE

Phase 1 : Disc out of the box

The disc was tested without undergoing any specific processing before testing. Present were some dust particles and handling defects such as minor scratches and fingerprints.

| Blu-Ray burner |

Liteon LH-2B1S vAL05 |

| Disc |

TDK BD-RE 25GB |

|

| Media ID |

TDKBLDWBA (000) |

Writing speed |

|

- Measurements

Digital errors

Jitter

Reflectivity modilation

Reflectivity

Servo & Tracking parameters - RADIAL2

All signals

16. Measurements - Plextor PX-B900A 2x & Verbatim BD-R

Phase 1 : Disc out of the box

The disc was tested without undergoing any specific processing before testing. Present were some dust particles and handling defects such as minor scratches and fingerprints.

| Blu-Ray burner |

Plextor PX-B900A v1.00 |

| Disc |

Verbatim BD-R 25GB |

|

| Media ID |

VERBATIMa (000) |

Writing speed |

|

- Measurements

Digital errors

Jitter

Reflectivity modulation

Reflectivity

Servo & Tracking parameters - RADIAL2

All signals

17. Measurements - Plextor PX-B900A 2x & TDK BD-R

Phase 1 : Disc out of the box

The disc was tested without undergoing any specific processing before testing. Present were some dust particles and handling defects such as minor scratches and fingerprints.

| Blu-Ray burner |

Plextor PX-B900A v1.00 |

| Disc |

TDK BD-R 25GB |

|

| Media ID |

TDKBLDRBA (000) |

Writing speed |

|

- Measurements

Digital errors

Jitter

Reflectivity modulation

Servo & Tracking parameters - RADIAL2

All signals

The measurements reveal an extremely high UNC error count.

Pass 2 : Disc cleaned

Due to the extremely high UNC errors on this disc, we ran the measurements a second time after the disc was cleaned using air spray and special tissues. The results are illustrated below.

Digital errors

All signals

The results are impressive. Cleaning the discs's surface resulted in an amazingly lower UNC count (1), as well as lower BEC and BEL error rates. This behavior was expected since from what we have seen, Blu-Ray discs are extremely sensitive to dust and defects on the disc surface.

Rest of measurements:

Jitter - JFli, JRLi |

Reflectivity Modulation- I8/I8H |

|

|

Reflectivity R8H, R8Hrv |

RADIAL 2 |

|

|

18. Measurements - Plextor PX-B900A 2x & Verbatim BD-RE

Pass 1 : Disc out of the box

The disc was tested without undergoing any specific processing before testing. Present were some dust particles and handling defects such as minor scratches and fingerprints.

| Blu-Ray burner |

Plextor PX-B900A v1.00 |

| Disc |

Verbatim BD-RE 25GB |

|

| Media ID |

VERBATIM0 (000) |

Writing speed |

|

- Measurements

Digital errors

Jitter

Reflectivity

Reflectivity modulation

Mechanical parameters - RADIAL2

All signals

Pass 2 : Disc cleaned

The specific disc was cleaned using professional air spray and special tissues. The disc was measured again, and the results are illustrated below.

Digital errors

Again, cleaning the disc lead to completely different results. All digital errors were lower this time, and specifically, the UNC maximum value was limited to 2 (as opposed to 2728 previously), and the average UNC count is down to 15T from 5456T.

All signals

Rest of measurements:

Jitter - JFli, JRLi |

Reflectivity Modulation- I8/I8H |

|

|

Reflectivity R8H, R8Hrv |

RADIAL 2 |

|

|

19. Summary

The purpose of this article is to provide an introduction to the measuring signals related to the evaluation of the quality of a Blu-Ray recorded disc. Of course, evaluating quality with the various drives and media we used was also a goal, but it should be left aside for now, since the technology is still trying to get a stable foothold on the market.

The discs we used in the test were burned at 2X and some at 4X. Regarding the recording process, it seems that both the 2X and 4x writing strategies are quite efficient. The measurements showed that the pit/land shape was adequate. In addition, the reflectivity, a basic parameter in optical media, is also very good and stable over the disc. On the other hand, we cannot neglect the fact that uncorrectable digital errors occurred with many discs. But these cannot be attributed solely to the writing process, since handling and its affects on the media plays a major role.

The Blu-Ray disc format uses a laser with a Numerical Aperture of 0.85nm. This means that the laser beam that accesses the data is very narrow, compared to CD and DVD. As a result, the laser beam can be easily diffracted by small particles or defects that exist on the disc's surface. The size of these particles could be microscopic, as in the case of the dust or smoke. In the picture below you can see how a particle interferes with the laser beam of a reader in the CD, DVD and Blu-Ray disc formats.

Our test measurements confirmed this. The cleanliness of the read side of the media seems to have a great impact on the disc quality. For example, there were cases where discs were measured and produced very high Uncorrectable errors. Of course, these discs were out of specifications and as a result, they should have been rejected. But after cleaning the discs with special air spray and appropriate tissues, we re-measured them (Pass 2), and UNC errors were dramatically reduced or even disappeared altogether.

Cleaning the disc surface of a disc before reading/testing was essential in the case of previous generations of optical media (CD and DVD) but as the pit/land structure is much smaller on high definition media, even particles of dust - not to mention fingerprints - make playback quite difficult, which correspond to extremely high peaks in digital errors during measurements.

Despite the existence of UNC errors, the DaTARIUS driveCube system did not lose track. In addition, the discs used in this test were readable with commercial Blu-Ray drives.

However, it would not be wise to make a clear statement on the playability of the Blu-Ray media of this test in a consumer environment. From a technical point of view, the discs we tested were in some cases out of specifications, but as seen with DVD video, digital errors do not always lead to video/audio distortion. We aim to do a more in depth study of high definition media by creating a batch of discs with video content and have the discs tested on a panel of consumer players available on the market.

For now, our first test with Blu-Ray media brought to the surface a serious parameter related to Blu-Ray discs: The necessity for very careful handling and storage.