Microsoft is Improving Camera Performance Through Curved Image Sensors

While significant advances have been made to camera sensors and the algorithms that process images, optical systems have not seen the same radical improvements. Microsoft researchers set out to solve one of the most well-known optical issues in conventional photography: field curvature.

Field curvature exists because lenses don't want to focus on a plane. The lens delivers sharpest focus along a curved path, rather than on a flat surface. The result: objects appear out of focus across the image. By curving the focal surface, the need for the lens to address field curvature is eliminated and the resulting lens design freedom can be used to improve other aspects of the system.

There are multiple approaches to curve the focal surface. Some work well in specific circumstances (for example, curved arrays of flat sensors can be useful in astronomical telescopes), but most known techniques fail in conventional, human-scale cameras. An obvious approach would be to bend the sensor itself, but since silicon sensors are monocrystalline, they are prone to shattering rather than bending.

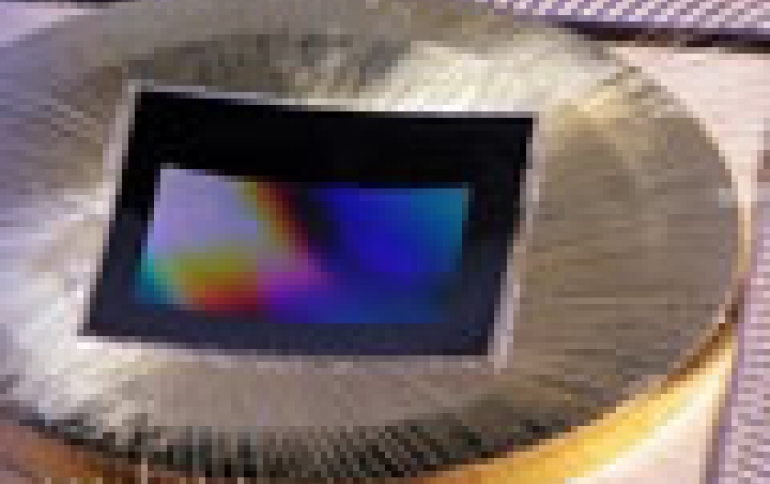

Several companies have attempted to bend silicon, but attaining useful amounts of curvature has remained elusive. To address these limitations, Microsoft researchers joined together on Project Vermont - a project designed to push the limits of silicon sensor curvature and deliver substantial camera performance improvements.

The team designed numerous optical models and built several early prototypes to validate their hypotheses regarding these improvements. Those early successes helped the researchers identify key opportunities to attain higher degrees of curvature. They then collaborated with scientists at HRL Laboratories to capitalize on these opportunities. In a new paper, Highly curved image sensors: a practical approach for improved optical performance , published today in Optics Express, Microsoft's team outlines the various techniques we developed to attain useful amounts of curvature and shows empirical prototype results.

What does Project Vermont mean for the future of cameras? Curving the image surface can dramatically improve performance along many axes - resolution, light-gathering, and illumination uniformity - while also reducing system size, cost, and complexity. While the amount of improvement is dependent on many camera system variables, including focal length, sensor size, and lens complexity, Project Vermont showed substantial progress over previous approaches.

In Microsoft's most recent research prototype, the researchers significantly outperformed a premium 35mm digital single- lens reflex camera (DLSR) in both sharpness and uniformity of illumination, using a much smaller cellphone-sized sensor. At present, Microsoft's prototype camera system is sharper (in terms of line pairs per picture height) than any known commercially available consumer camera.

Applying this technique to cellphones will require additional research and engineering. However, for more conventional camera systems, Microsoft sees a near-term opportunity for significant improvement.