NU Combo DBW-521

5. DVD Error Correction Tests

Review Pages

2. Data CD Reading Tests

3. CD Error Correction Tests

4. DVD reading tests

5. DVD Error Correction Tests

6. Protected Disc Tests

7. DAE Tests

8. CD Recording Tests

9. Writing Quality Tests - 3T Jitter Tests

10. Writing Quality Tests - C1 / C2 Error Measurements

11. Conclusion

NU COMBI DBW-521 - Page 5

DVD Error Correction Tests

In the following tests we examined the DVD reading capabilities of the NU with scratched / defective DVD media. For the tests we used CDVD Benchmark and Nero CDSpeed. The reference test media came from ALMEDIO.

- Single Layer media

ABEX TDR-821

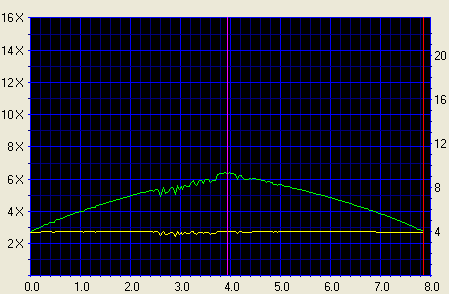

This

is a single sided, single layer DVD-ROM with 4.7GB capacity, and its surface

has an artificial scratch of dimensions varying from 0.4 to 3.0 mm. The following

transfer rate picture comes from the CDVD Benchmark v1.21 transfer rate test.

This

is a single sided, single layer DVD-ROM with 4.7GB capacity, and its surface

has an artificial scratch of dimensions varying from 0.4 to 3.0 mm. The following

transfer rate picture comes from the CDVD Benchmark v1.21 transfer rate test.

The first test with the NU combo drive indicates that the device may be weak in the area of DVD error correction. The drive logged in read errors during the reading process of this relatively simple test disc from Abex, the 821 test disc. The tested NU device had problems reading the first stages of the defective area, in the inner part of the disc where the read errors occurred (red dot on the graph). Despite the read error, the overall strategy of the drive was not affected, with the drive changing reading speeds to overcome this initial hurdle. The CAV reading strategy was maintained with no other errors occurring.

ABEX TDR-825

This is also a single sided, single layer DVD-ROM with 4.7GB capacity. The data structure of the disc is exactly the same as that of the TDR-821, with the difference that there are no scratches on the surface and instead defective areas ranging in dimensions from 0.5 to 1.1 mm. There are also fingerprints with height between 65 and 75 micrometers.

This is also a single sided, single layer DVD-ROM with 4.7GB capacity. The data structure of the disc is exactly the same as that of the TDR-821, with the difference that there are no scratches on the surface and instead defective areas ranging in dimensions from 0.5 to 1.1 mm. There are also fingerprints with height between 65 and 75 micrometers.

The above screenshot defies the initial indications as to the drives capabilities when it comes to DVD error correction. The 825 Abex test disc is more difficult than the previous test disc, but it posed no problems for the NU. The drive read all defective areas without problems and the test finished without read errors.

- Dual Layer media

ABEX TDR-841

This is an 8.5GB dual layer, single sided DVD-ROM disc with artificial scratches of dimensions ranging from 0.4 to 3.0mm, on both layers.

This is an 8.5GB dual layer, single sided DVD-ROM disc with artificial scratches of dimensions ranging from 0.4 to 3.0mm, on both layers.

The NU managed to read the first dual layer test disc without problems. Both layers were read quickly, and without read errors.

ABEX TDR-845

This disc is a single sided, dual layer DVD-Rom disc with capacity of 8.5GB. The only difference between the TDR-845 and the TDR-841 is that the first includes both defective areas and fingerprints. The dimensions of the defective areas range from 0.5 to 1.1 mm and the fingerprints have height sized from 65 to 75 microns (micrometres).

This disc is a single sided, dual layer DVD-Rom disc with capacity of 8.5GB. The only difference between the TDR-845 and the TDR-841 is that the first includes both defective areas and fingerprints. The dimensions of the defective areas range from 0.5 to 1.1 mm and the fingerprints have height sized from 65 to 75 microns (micrometres).

Once again very good reading performance. Fast reading speed without errors throughout the test.

ABEX TDV-541

The TDV-541 is a single sided, dual layer DVD-VIDEO disc, with a capacity of 8.5GB.The disc is based on the TDV-540 series which is designed for inspection and adjustment of DVD-VIDEO players. The disc checks the layer switch operation from layer 0 to layer 1 and also includes test pictures and test signals for DVD sound files. The current TDV-541 also checks the error correcting capabilities of the drive and includes scratches sized from 0.4 to 3.0 mm.

The TDV-541 is a single sided, dual layer DVD-VIDEO disc, with a capacity of 8.5GB.The disc is based on the TDV-540 series which is designed for inspection and adjustment of DVD-VIDEO players. The disc checks the layer switch operation from layer 0 to layer 1 and also includes test pictures and test signals for DVD sound files. The current TDV-541 also checks the error correcting capabilities of the drive and includes scratches sized from 0.4 to 3.0 mm.

The drive managed to read and finish the 541 ABex test discs without errors and without problems during the layer switch.

ABEX TDV-545

The TDV-545 disc is based on the TDV-540 series. It is a single sided, dual layer Video/S-2 disc with a capacity of 8.5GB. The TDV-545 includes artificial black dots on the disc's surface, sized from 0.4 to 1.0 mm. It also has 65 - 75 micrometres high fingerprints.

The TDV-545 disc is based on the TDV-540 series. It is a single sided, dual layer Video/S-2 disc with a capacity of 8.5GB. The TDV-545 includes artificial black dots on the disc's surface, sized from 0.4 to 1.0 mm. It also has 65 - 75 micrometres high fingerprints.

This disc was not problem for the NU drive.

Review Pages

2. Data CD Reading Tests

3. CD Error Correction Tests

4. DVD reading tests

5. DVD Error Correction Tests

6. Protected Disc Tests

7. DAE Tests

8. CD Recording Tests

9. Writing Quality Tests - 3T Jitter Tests

10. Writing Quality Tests - C1 / C2 Error Measurements

11. Conclusion