Writing Quality

19. JVC ENC K2

Review Pages

2. Pits and Lands

3. Error Correction - Page 1

4. Error Correction - Page 2

5. Error Correction - Page 3

6. CIRC - Page 1

7. CIRC - Page 2

8. CD Decoding system

9. C1/C2 Errors - Page 1

10. C1/C2 Errors - Page 2

11. EFM - Page 1

12. EFM - Page 2

13. Jitter - Page 1

14. Jitter - Page 2

15. Jitter - Page 3

16. Oscilloscope

17. Jitter at DVD

18. Technologies for Reducing Jitter

19. JVC ENC K2

20. AudioMASTER

21. VariREC

22. TEAC Boost Function

23. Testing Equipement - Page 1

24. Testing Equipement - Page 2

25. Calibration media

26. Tests before recording

27. Tests after recording

28. Atomic Force Microscopy

Writing Quality - Page 19

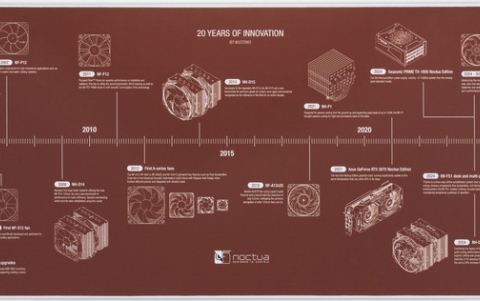

JVC "ENC K2"

The following information is taken directly from JVC's website. Since this technology is used only in pressed discs is presented as was originally posted. For more more information visit JVC's Japanese website.

![]() Victor

Company of Japan, Limited (JVC) and Victor Entertainment, Inc., at 6th of November

2002 announced the co-development of "Encode K2" (ENC K2) technology

that according to JVC brings dramatic improvements in sound quality to formats

such as CD and DVD Audio during the manufacturing process. The development of

ENC K2 has been made possible by the application of JVC's proprietary "K2

Technology" during the CD format encoding process.

Victor

Company of Japan, Limited (JVC) and Victor Entertainment, Inc., at 6th of November

2002 announced the co-development of "Encode K2" (ENC K2) technology

that according to JVC brings dramatic improvements in sound quality to formats

such as CD and DVD Audio during the manufacturing process. The development of

ENC K2 has been made possible by the application of JVC's proprietary "K2

Technology" during the CD format encoding process.

JVC will employ the technology on CCCDs to be released on November 13, 2002, and display the logo marks on the left as a guarantee of a musical presence virtually identical to that of the original master tapes (http://www.jvcmusic.co.jp/cccd).

In the quest to convey "the truth of the music" accurately, the two companies have worked together for years to develop technologies that improve the sound quality of disc media, aiming to achieve faithful reproduction on CD of the musical quality of original master tapes.

Based on conventional K2 Technology, ENC K2 reproduces a musical presence virtually identical to that achieved on the original master tapes. ENC K2 technology eliminates any artifacts that might alter or degrade sound quality from the digital signal transmission and occur during the CD format encoding process, such as distortion and noise.

- Background information

Theoretically, the quality of digital audio should not change as long as codes

remain constant. In fact, however, it is modified during digital signal transmission.

The CD cutting process used when manufacturing CDs usually includes three processes:

"Reproduction of Master Tapes," "CD Format Encoding Process,"

and "Laser Cutting Process." Most recently, PC software and copy control

functions have been introduced as a part of the "CD format encoding"

process.

ENC K2 was developed to eliminate the artifacts that alter sound quality from digital signal transmission from input to output during the "CD format encoding" process; a process which is becoming increasingly multi-functional. (See Chart 1 on the next pages.)

The two companies have jointly developed and introduced technologies to improve music quality based on their proprietary K2 technology, including "Digital K2" which eradicates alterations in the audio quality of master tapes and "K2 Laser Cutting," (K2 LC) which improves the precision and purity of laser cutting during the CD cutting process.

With the development of ENC K2, the companies have established the Full Code Transfer System at all processes during the cutting process in CD manufacturing. (See Chart 2 on the next pages.)

- "K2 Technology" and "ENC K2"

Theoretically, the quality of digital audio should not change as long as codes remain constant. In fact, however, it is modified during digital signal transmission. This occurs due non-code components, such as "ripple" and "jitter," which exist in digital signals. "K2 Interface," the first version of the two companies' proprietary K2 technology, was developed in 1987. This technology instantly reads only "1" and "0," logical codes from all digital signals including those that change the music quality, then recreates new digital signals. With this technology, the companies succeeded in eliminating any quality modifying factors from digital signal transmission. JVC has successfully inserted "ENC K2" in the CD format encoding process by adapting "K2 Technology" to EFM and controlling data synchronization.

The companies realized the "Master Direct" concept, in which every CD faithfully reproduces the music quality of master tapes, by establishing the "Full Code Transfer System." This system removes the factors that alter music quality during the three most important CD cutting processes: "Reproduction of Master Tapes," "CD Format Encoding Process," and "Laser Cutting Process."

Review Pages

2. Pits and Lands

3. Error Correction - Page 1

4. Error Correction - Page 2

5. Error Correction - Page 3

6. CIRC - Page 1

7. CIRC - Page 2

8. CD Decoding system

9. C1/C2 Errors - Page 1

10. C1/C2 Errors - Page 2

11. EFM - Page 1

12. EFM - Page 2

13. Jitter - Page 1

14. Jitter - Page 2

15. Jitter - Page 3

16. Oscilloscope

17. Jitter at DVD

18. Technologies for Reducing Jitter

19. JVC ENC K2

20. AudioMASTER

21. VariREC

22. TEAC Boost Function

23. Testing Equipement - Page 1

24. Testing Equipement - Page 2

25. Calibration media

26. Tests before recording

27. Tests after recording

28. Atomic Force Microscopy