ARM and TSMC Collaborate to Optimize 64-bit ARM Processors for FinFET Process Technology

Processor IP licensor ARM and foundry chip maker Taiwan Semiconductor Manufacturing Co. Ltd. (TSMC) have signed a multi-year agreement to work together to optimize next-generation 64-bit ARM processor cores for FinFET process technology.

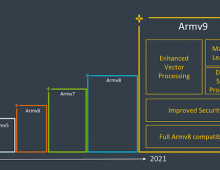

The two companies extend their collaboration beyond 20-nanometer (nm) technology to deliver ARM processors on FinFET transistors. The collaboration will optimize the next generation of 64-bit ARM processors based on the ARMv8 architecture, ARM Artisan physical intellectual property (IP), and TSMC?s FinFET process technology for use in mobile and enterprise markets that require both high performance and energy efficiency.

The collaboration will enable sharing of technical information and feedback between the two companies, enhancing the development of ARM IP and TSMC process technology. ARM will leverage process information to optimize the power, performance and area (PPA) of the overall solution to reduce risk and encourage early adoption. TSMC will use the latest ARM processors and technology to benchmark and tune advanced FinFET process technologies. The collaboration will result in improved silicon process, physical IP and processor technology that together will enable new system-on-chip (SoC) innovation and shorten time-to-market.

The ARMv8 architecture has been designed specifically to enable energy-efficient implementations. Similarly, the 64-bit memory addressing and high-end performance are necessary to enable enterprise computing and network infrastructure that are fundamental for the mobile and cloud-computing markets.

TSMC's FinFET process promises impressive speed and power improvements as well as leakage reduction. All of these advantages overcome challenges that have become critical barriers to further scaling of advanced SoC technology.

"By working closely with TSMC, we are able to leverage TSMC's ability to quickly ramp volume production of highly integrated SoCs in advanced silicon process technology," said Simon Segars, executive vice president and general manager, Processor and Physical IP Divisions, ARM. "The ongoing deep collaboration with TSMC provides customers earlier access to FinFET technology to bring high-performance, power-efficient products to market."

"This collaboration brings two industry leaders together earlier than ever before to optimize our FinFET process with ARM?s 64-bit processors and physical IP," said Cliff Hou, vice president, TSMC Research & Development. "We can successfully achieve targets for high speed, low voltage and low leakage, thereby satisfying the requirements of our mutual customers and meeting their time-to-market goals."

The companies did not indicate what process nodes are covered by the agreement but TSMC is not expected to introduce a FinFET manufacturing process until a 16-nm manufacturing process.

Rival foundry UMC has licensed a 20-nm FinFET manufacturing process from IBM.

Over the last few months TSMC has been unable to provide enough 28nm wafers for some of its customers, although uncertainty remains about whether this is the result of lower than expected yields on certain designs or higher than expected demand.

The collaboration will enable sharing of technical information and feedback between the two companies, enhancing the development of ARM IP and TSMC process technology. ARM will leverage process information to optimize the power, performance and area (PPA) of the overall solution to reduce risk and encourage early adoption. TSMC will use the latest ARM processors and technology to benchmark and tune advanced FinFET process technologies. The collaboration will result in improved silicon process, physical IP and processor technology that together will enable new system-on-chip (SoC) innovation and shorten time-to-market.

The ARMv8 architecture has been designed specifically to enable energy-efficient implementations. Similarly, the 64-bit memory addressing and high-end performance are necessary to enable enterprise computing and network infrastructure that are fundamental for the mobile and cloud-computing markets.

TSMC's FinFET process promises impressive speed and power improvements as well as leakage reduction. All of these advantages overcome challenges that have become critical barriers to further scaling of advanced SoC technology.

"By working closely with TSMC, we are able to leverage TSMC's ability to quickly ramp volume production of highly integrated SoCs in advanced silicon process technology," said Simon Segars, executive vice president and general manager, Processor and Physical IP Divisions, ARM. "The ongoing deep collaboration with TSMC provides customers earlier access to FinFET technology to bring high-performance, power-efficient products to market."

"This collaboration brings two industry leaders together earlier than ever before to optimize our FinFET process with ARM?s 64-bit processors and physical IP," said Cliff Hou, vice president, TSMC Research & Development. "We can successfully achieve targets for high speed, low voltage and low leakage, thereby satisfying the requirements of our mutual customers and meeting their time-to-market goals."

The companies did not indicate what process nodes are covered by the agreement but TSMC is not expected to introduce a FinFET manufacturing process until a 16-nm manufacturing process.

Rival foundry UMC has licensed a 20-nm FinFET manufacturing process from IBM.

Over the last few months TSMC has been unable to provide enough 28nm wafers for some of its customers, although uncertainty remains about whether this is the result of lower than expected yields on certain designs or higher than expected demand.