ASML to Buy Cymer to Accelerate Development Of EUV Technology

ASML Holding NV, Europe's largest semiconductor equipment maker and Cymer, Inc., a supplier of lithography light sources used by chipmakers to manufacture advanced semiconductor devices, announced that they have entered into a definitive agreement under which ASML will acquire all outstanding shares of Cymer in a cash-and-stock transaction currently valued at EUR 1.95 billion.

The purpose of the acquisition of Cymer is to accelerate the development of Extreme Ultraviolet (EUV) semiconductor lithography technology. EUV is vital to support the semiconductor industry's transition to the next manufacturing technology, which is needed to create microchips with more functions at a lower cost and that are more energy-efficient, consistent with Moore's Law.

ASML and Cymer have collaborated closely for over a year. Combining Cymer's expertise in EUV light sources with ASML's expertise in lithography systems design and integration will reduce the risk and accelerate the introduction of this complex technology.

The transaction, which was unanimously approved by the boards of directors of ASML and Cymer, would entitle each Cymer shareholder to receive US$20.00 in cash and a fixed ratio of 1.1502 ASML ordinary shares per Cymer share. The total price reflects a premium of 61 percent over Cymer's 30-day volume-weighted average price (VWAP) and 52 percent over its 90-day VWAP, using ASML's VWAP for the comparable period ending 16 October 2012.

"We believe that this transaction will improve our capabilities to bring new technologies to our customers, and will deliver value to Cymer's and ASML's shareholders," said Eric Meurice, President and Chief Executive Officer of ASML. "We expect the merger to make EUV technology development significantly more efficient and simplify the supply chain and integration flow of the EUV modules. We are also very much encouraged by the opportunities that we expect to create around Cymer's growing advanced Immersion systems and dry Deep Ultraviolet (DUV) Installed Base Products (IBP) business."

"Over the last several years, Cymer has been investing significant capital towards developing EUV source technology. We are very encouraged that ASML's resources will enable the combined company to continue to develop and successfully commercialize EUV on an accelerated time frame," said Bob Akins, Chairman and Chief Executive Officer of Cymer. "The success of EUV is critical to the semiconductor industry, and we view this merger as very attractive for our shareholders, customers and employees as well as our industry."

As a result of the transaction, ASML will also acquire Cymer's DUV business. This technology is expected to remain a significant and growing engine of sales and profit and will be well positioned to support and balance customer needs for EUV and immersion multiple patterning. ASML intends to manage Cymer's commercial operations as an independent division based in the United States, and will continue to deliver and service DUV and EUV sources for all customers on an arm's length basis. ASML scanners will continue to interface with light sources from all manufacturers.

The transaction is expected to close in the first half of 2013 and is subject to customary closing conditions, including review by U.S. and international regulators and approval by Cymer's shareholders.

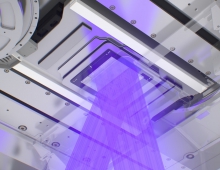

ASML's 6 pre-production NXE:3100 EUV systems, capable of resolution performance compatible with the 22 nm node in single patterning mode, have exposed more than 23,000 wafers at the company's customer sites with good overlay and imaging performance, enabling semiconductor device recipe development and confirmation of infrastructure progress. The successor system, the NXE:3300B, is capable of resolution performance compatible with the 14 nm node in single patterning mode. This system has already shown overlay down to 1.3 nm and imaging down to 16 nm in a full-field single exposure using new illumination technology. Progress continues on improving the productivity of the EUV systems currently limited by the light source.

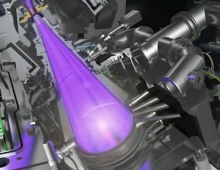

Cymer's EUV light sources have for some time been exposing wafers at up to 11 Watts source power at customer facilities, resulting in NXE:3100 productivity of up to 7 wafers per hour. ASML and Cymer jointly made significant progress during the summer and have now proven in laboratories a sustained 30-Watt source exposure power potential, which would enable the NXE:3300B to expose 18 wafers per hour. ASML's specified target remains at 105 Watts or 69 wafers per hour (wph), to be achieved for 2014 microchip production.

The companies plan to deliver the first 11 NXE:3300B systems in 2013 to be installed at their customers for R&D.

Additional orders for NXE:3300B systems intended for production in 2014 at a minimum specification targeting 69 wph.

ASML and Cymer have collaborated closely for over a year. Combining Cymer's expertise in EUV light sources with ASML's expertise in lithography systems design and integration will reduce the risk and accelerate the introduction of this complex technology.

The transaction, which was unanimously approved by the boards of directors of ASML and Cymer, would entitle each Cymer shareholder to receive US$20.00 in cash and a fixed ratio of 1.1502 ASML ordinary shares per Cymer share. The total price reflects a premium of 61 percent over Cymer's 30-day volume-weighted average price (VWAP) and 52 percent over its 90-day VWAP, using ASML's VWAP for the comparable period ending 16 October 2012.

"We believe that this transaction will improve our capabilities to bring new technologies to our customers, and will deliver value to Cymer's and ASML's shareholders," said Eric Meurice, President and Chief Executive Officer of ASML. "We expect the merger to make EUV technology development significantly more efficient and simplify the supply chain and integration flow of the EUV modules. We are also very much encouraged by the opportunities that we expect to create around Cymer's growing advanced Immersion systems and dry Deep Ultraviolet (DUV) Installed Base Products (IBP) business."

"Over the last several years, Cymer has been investing significant capital towards developing EUV source technology. We are very encouraged that ASML's resources will enable the combined company to continue to develop and successfully commercialize EUV on an accelerated time frame," said Bob Akins, Chairman and Chief Executive Officer of Cymer. "The success of EUV is critical to the semiconductor industry, and we view this merger as very attractive for our shareholders, customers and employees as well as our industry."

As a result of the transaction, ASML will also acquire Cymer's DUV business. This technology is expected to remain a significant and growing engine of sales and profit and will be well positioned to support and balance customer needs for EUV and immersion multiple patterning. ASML intends to manage Cymer's commercial operations as an independent division based in the United States, and will continue to deliver and service DUV and EUV sources for all customers on an arm's length basis. ASML scanners will continue to interface with light sources from all manufacturers.

The transaction is expected to close in the first half of 2013 and is subject to customary closing conditions, including review by U.S. and international regulators and approval by Cymer's shareholders.

ASML's 6 pre-production NXE:3100 EUV systems, capable of resolution performance compatible with the 22 nm node in single patterning mode, have exposed more than 23,000 wafers at the company's customer sites with good overlay and imaging performance, enabling semiconductor device recipe development and confirmation of infrastructure progress. The successor system, the NXE:3300B, is capable of resolution performance compatible with the 14 nm node in single patterning mode. This system has already shown overlay down to 1.3 nm and imaging down to 16 nm in a full-field single exposure using new illumination technology. Progress continues on improving the productivity of the EUV systems currently limited by the light source.

Cymer's EUV light sources have for some time been exposing wafers at up to 11 Watts source power at customer facilities, resulting in NXE:3100 productivity of up to 7 wafers per hour. ASML and Cymer jointly made significant progress during the summer and have now proven in laboratories a sustained 30-Watt source exposure power potential, which would enable the NXE:3300B to expose 18 wafers per hour. ASML's specified target remains at 105 Watts or 69 wafers per hour (wph), to be achieved for 2014 microchip production.

The companies plan to deliver the first 11 NXE:3300B systems in 2013 to be installed at their customers for R&D.

Additional orders for NXE:3300B systems intended for production in 2014 at a minimum specification targeting 69 wph.