Epson Develops Print Head Using an OLED Light Source

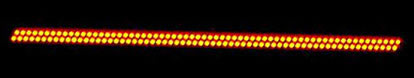

Seiko Epson Corporation has successfully developed the world's first print head using an OLED (organic light-emitting diode) light source.

In addition to its development of OLED displays, Epson has researched the characteristics of OLED as an electronic device. Specifically, Epson has succeeded in creating a print head that uses OLED as a light source (OLED print head), opening the way for utilization of OLED as a new printing technology for printers.

At present, electrophotographic printing technologies for copiers and printers use either laser or LED light sources. Epson partnered with Sumitomo Chemical Co., Ltd. to jointly develop a super bright OLED that can be used in printing. Printing tests using a prototype of an OLED-based print head have produced printouts quality comparable to or better than those produced by conventional laser printers, acording to the company.

OLED is formed through a process in which OLED material is applied directly onto a glass substrate, making it possible for a single substrate to have a linear light source. This enables the exact amount of light to be used to irradiate a spot with high accuracy to form highly uniform images, and for print heads to be made very small and ultra thin. Going forward, it will be possible to merge OLED technology with Epson's low-temperature polysilicon TFT technology to achieve both higher printing resolutions and cost reductions by incorporating an IC into the print head.

Epson believes that the new technology will play a vital role in fulfilling the need for color printers that are smaller, have higher resolution, and faster printing speeds.

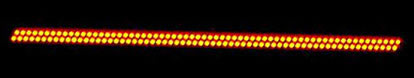

At present, electrophotographic printing technologies for copiers and printers use either laser or LED light sources. Epson partnered with Sumitomo Chemical Co., Ltd. to jointly develop a super bright OLED that can be used in printing. Printing tests using a prototype of an OLED-based print head have produced printouts quality comparable to or better than those produced by conventional laser printers, acording to the company.

OLED is formed through a process in which OLED material is applied directly onto a glass substrate, making it possible for a single substrate to have a linear light source. This enables the exact amount of light to be used to irradiate a spot with high accuracy to form highly uniform images, and for print heads to be made very small and ultra thin. Going forward, it will be possible to merge OLED technology with Epson's low-temperature polysilicon TFT technology to achieve both higher printing resolutions and cost reductions by incorporating an IC into the print head.

Epson believes that the new technology will play a vital role in fulfilling the need for color printers that are smaller, have higher resolution, and faster printing speeds.