NEDO and Panasonic Achieve a 16.09 percent Conversion Efficiency in Largest-area Perovskite Solar Cell Module

Panasonic Corp. says it has achieved the world's highest energy conversion efficiency of 16.09% for a perovskite solar module.

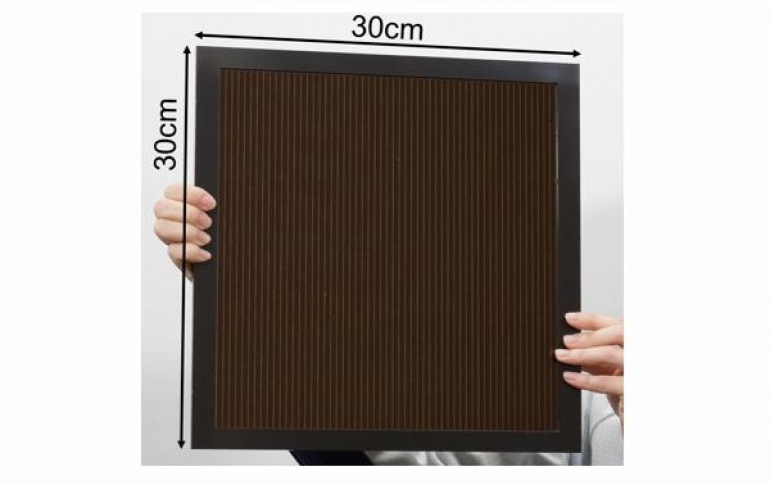

The module (aperture area 802 cm2: 30 cm long x 30 cm wide x 2 mm thick) featured Panasonic's newly developed lightweight technology -- a glass substrate and a large-area coating method based on inkjet printing was applied.

This was carried out as part of the project of the New Energy and Industrial Technology Development Organization (NEDO), which is working on the "Development of Technologies to Reduce Power Generation Costs for High-Performance and High-Reliability Photovoltaic Power Generation" to promote the widespread adoption of solar power generation.

The crystalline silicon solar cells, which have been most widely used in the world, have found markets in Japan in such fields as mega-solar, residential, factory and public facilities. To penetrate further into these markets as well as secure new markets, it is crucial to make solar modules lighter and larger.

Perovskite solar cells - solar cells whose light-absorbing layer is composed of perovskite crystals - have a structural advantage as their thickness including a power generation layer is only one-hundredth of that of crystalline silicon solar cells, so that perovskite modules can be lighter in weight than crystalline silicon modules. The lightweight property enables various placing styles such as installing on façades and windows by using transparent conductive electrode, which can lead to the wide-spread adoption of Net Zero Energy Buildings. Further, as each layer can be coated onto the substrates directly, they can be produced cheaper, compared to the conventional process technology.

On the other hand, despite perovskite technology achieved 25.2% power conversion efficiency, comparable to crystalline silicon solar cells, in small size cells, it was very difficult to deposit materials uniformly all over large-area by conventional technology. As a result, the power conversion efficiency was inclined to decrease.

Among the atomic groups that formed perovskite crystal, methylamine has thermal stability issue during the heating process during module production (methylamine is removed from perovskite crystal by heat, as a result, a certain part of crystal is destroyed). By altering certain part of methylamine into Formamidinium, Cesium, Rubidium that have appropriate atom diameter size, Panasonic showed that this method is efficient for crystal stabilization and leads to contribute to high power conversion efficiency.

In the thin film forming process with Panasonic's inkjet coating method, there is the flexibility for coating pattern, while dot patterning of material and crystallization uniformity over each layer surface are essential. To satisfy these requirements, both by tuning the concentration of perovskite ink to certain content and by precisely controlling coating amount and speed during printing process, they realized high power conversion efficiency of large-area module.

By optimizing these technologies through coating process in each layer formation, Panasonic succeeded in enhancing crystal growth and improving the uniformity for thickness and crystal layer. As a result, they achieved the power conversion efficiency of 16.09% and took a step forward to practical application.

This inkjet-based coating method that can cover a large area reduces manufacturing costs of modules. In addition, this large-area, lightweight, and high-conversion efficiency module allows for generating solar power highly efficiently at locations where conventional solar panels were difficult to install, such as façades.

NEDO and Panasonic continue to improve perovskite layer materials, aiming to achieve high efficiency comparable to that of crystalline silicon solar cells and establish technologies for practical application in new markets.