NHK Showcases 8-inch Flexible OLED Display, Fast Holographic Recording Technique

The NHK's Science & Technology Research Laboratories (STRL) unveiled an 8-inch full-color flexible OLED display at the Open House 2013 event held earlier this week.

Using advanced technologies, STRL fabricated an 8-inch VGA (640 x 480) flexible OLED display with a resolution is 100ppi.

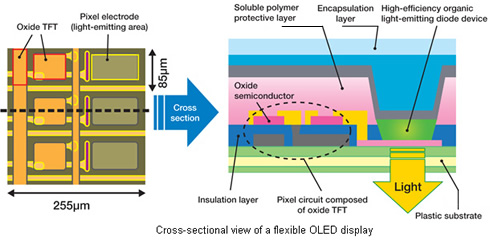

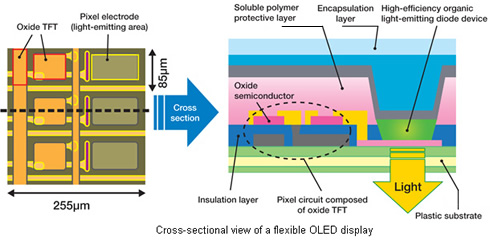

Researchers at STRL have been researching thin-film transistors (TFTs) as the driving devices and organic light-emitting diodes (OLEDs) as the light-emitting devices in flexible displays. They have fabricated flexible displays using new highly efficient phosphorescent OLEDs and oxide TFTs that are suitable for fabricating displays with large numbers of pixels.

The researchers have improved the materials used in the light-emitting layer and developed a red light-emitting device with one-third the power consumption and seven times the lifetime of conventional devices. The red phosphorescent material was made by combining a guest material developed by using a platinum (Pt) complex and a host material (benzoquinoline derivative).

During a presentation, STRL explained the oxide TFTs required for high-speed driving when increasing the number of pixels. The researchers employed an amorphous InGaZnO (a-IGZO) TFT for driving pixels. They used a-IGZO TFT because it is highly flexible and suited for large displays, the company said.

The protective layer for OLEDs was formed by applying a polymer material. The researchers used soluble polymer materials as the insulating layers for large-screen displays and fabricated TFTs with good switching characteristics.

They also developed a process for integrating TFTs on a plastic film at a fabrication temperature of about 200°C.

STRL plans will continue to improve the performance of TFTs and OLEDs in order to make larger displays with higher resolution, and we will continue to develop our fabrication techniques and materials in order to make larger screens.

The research on organic electroluminescent devices was conducted in collaboration with Nippon Shokubai Co., Ltd.

In cooperation with Astro Design Co., Ltd., NHK has also developed a portable camera capable of shooting 8k video (7,680 x 4,320 pixels, 60fps). The camera packs a 33-megapixel sensor and drive circuits into a mere four square inch package. The camera's weight is 2kg and its size is 12.5cm x 12.5cm x 15cm (W xH x D).

In cooperation with Astro Design Co., Ltd., NHK has also developed a portable camera capable of shooting 8k video (7,680 x 4,320 pixels, 60fps). The camera packs a 33-megapixel sensor and drive circuits into a mere four square inch package. The camera's weight is 2kg and its size is 12.5cm x 12.5cm x 15cm (W xH x D).

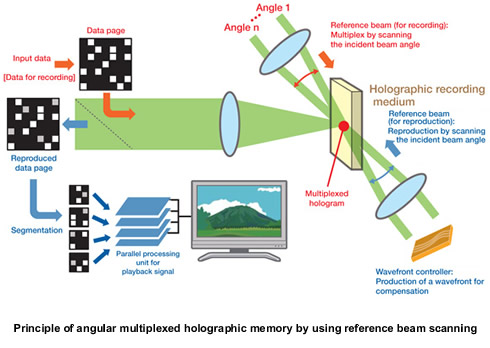

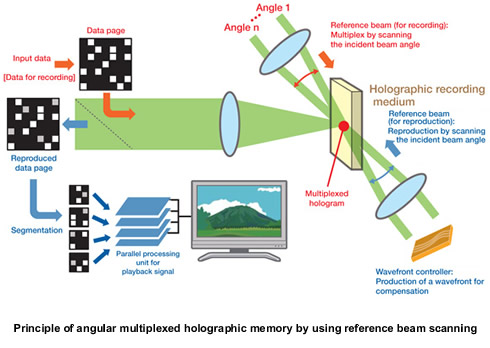

At the same event, STRL announced a holographic high-capacity recording technique, which could be used in order to produce a compact Super Hi-Vision recording equipment that uses thin optical discs.

The company showcased experimental equipment that can reproduce two-dimensional data pages at 500 Mbps, which is four times faster than the equipent STRL had showcased last year. STRL's low bit error rate recording technique that has four times the recording density of conventional technology for recording and playing back video data.

The researchers developed a new algorithm that rapidly acquires a two-dimensional data page that is reproduced from a hologram. The algorithm was implemented in a parallel processing unit and improved the transfer rate during reproduction of the disc.

When hologram distortion occurs due to volumetric changes in the holographic recording medium, data can be reproduced accurately by controlling the wavefront of the reference beam. An optical compensation circuit enables accurate data reproduction even with data pages of higher resolution and thereby increases the amount of data that can be stored per data page.

The research in the holographic storage technlology was conducted by STRl in collaboration with Nippon Steel & Sumikin Chemical Co., Ltd.

Researchers at STRL have been researching thin-film transistors (TFTs) as the driving devices and organic light-emitting diodes (OLEDs) as the light-emitting devices in flexible displays. They have fabricated flexible displays using new highly efficient phosphorescent OLEDs and oxide TFTs that are suitable for fabricating displays with large numbers of pixels.

The researchers have improved the materials used in the light-emitting layer and developed a red light-emitting device with one-third the power consumption and seven times the lifetime of conventional devices. The red phosphorescent material was made by combining a guest material developed by using a platinum (Pt) complex and a host material (benzoquinoline derivative).

During a presentation, STRL explained the oxide TFTs required for high-speed driving when increasing the number of pixels. The researchers employed an amorphous InGaZnO (a-IGZO) TFT for driving pixels. They used a-IGZO TFT because it is highly flexible and suited for large displays, the company said.

The protective layer for OLEDs was formed by applying a polymer material. The researchers used soluble polymer materials as the insulating layers for large-screen displays and fabricated TFTs with good switching characteristics.

They also developed a process for integrating TFTs on a plastic film at a fabrication temperature of about 200°C.

STRL plans will continue to improve the performance of TFTs and OLEDs in order to make larger displays with higher resolution, and we will continue to develop our fabrication techniques and materials in order to make larger screens.

The research on organic electroluminescent devices was conducted in collaboration with Nippon Shokubai Co., Ltd.

In cooperation with Astro Design Co., Ltd., NHK has also developed a portable camera capable of shooting 8k video (7,680 x 4,320 pixels, 60fps). The camera packs a 33-megapixel sensor and drive circuits into a mere four square inch package. The camera's weight is 2kg and its size is 12.5cm x 12.5cm x 15cm (W xH x D).

In cooperation with Astro Design Co., Ltd., NHK has also developed a portable camera capable of shooting 8k video (7,680 x 4,320 pixels, 60fps). The camera packs a 33-megapixel sensor and drive circuits into a mere four square inch package. The camera's weight is 2kg and its size is 12.5cm x 12.5cm x 15cm (W xH x D).

At the same event, STRL announced a holographic high-capacity recording technique, which could be used in order to produce a compact Super Hi-Vision recording equipment that uses thin optical discs.

The company showcased experimental equipment that can reproduce two-dimensional data pages at 500 Mbps, which is four times faster than the equipent STRL had showcased last year. STRL's low bit error rate recording technique that has four times the recording density of conventional technology for recording and playing back video data.

The researchers developed a new algorithm that rapidly acquires a two-dimensional data page that is reproduced from a hologram. The algorithm was implemented in a parallel processing unit and improved the transfer rate during reproduction of the disc.

When hologram distortion occurs due to volumetric changes in the holographic recording medium, data can be reproduced accurately by controlling the wavefront of the reference beam. An optical compensation circuit enables accurate data reproduction even with data pages of higher resolution and thereby increases the amount of data that can be stored per data page.

The research in the holographic storage technlology was conducted by STRl in collaboration with Nippon Steel & Sumikin Chemical Co., Ltd.