Toshiba Develops Fast 3D Metal Printer

Toshiba and Toshiba Machine have jointly developed a prototype of a three-dimensional (3D) metal printer that delivers fabrication speeds more than 10 times faster than that of powder bed fusion printers. 3D printing, also known as additive manufacturing, creates objects by depositing successive layers of material on a substrate, in a way analogous to inkjet printing. However, while inket printing is 2D, 3D printing can translate computer-aided design (CAD) plans into three-dimensional objects, building multiple layers into highly complex shapes and geometries.

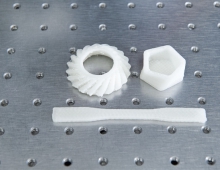

Toshibas new 3D printer uses laser metal deposition (LMD) technology that deposits powdered metal and delivers a laser beam in tandem. The laser heats the powder and sinters it, so that it fuses into a shaped agglomeration. The key to its high speed operation is a new nozzle based on Toshibas know-how in fluid simulation technology. The nozzle reduces the area to which metal particles are injected, and the laser beam focuses very precisely on the tiny area covered by the powder. The prototype achieves a fabrication speed of 110cc an hour with an 800-watt laser output, and can build larger structures at a lower cost than current methods, according to Toshiba. The printer works with a wide range of materials, including stainless steel, Inconel and iron.

Toshiba and Toshiba Machine will continue development on the prototype to secure further increases in fabrication speed and resolution, and to fine-tune interfacing with 3D CAD software. The companies aim to bring the printer into practical use in or after 2017.

The new printer will be showcased at Monozukuri Matching Japan 2015 at Tokyo Big Sight from December 2 to 4.