HAMR and MAMR Magnetic Storage Principles

Seagate and Western Digital are pursuing different technologies to push the limits of hard disk drives, with the goal to increase the areal density of hard disks.

The first public announcements from both hard disk makers appeared in 2017. Western Digital pledged to begin shipping drives based on what is known as microwave-assisted magnetic recording (MAMR) in 2019, and Seagate said it would have drives that incorporate heat-assisted magnetic recording (HAMR) on the market by 2020.

Obviously, both companies believe that hard drives are still the affordable choice for enterprise storage needs compared to the faster and more expensive solid-state drives built on flash memory.

Currently, Seagate aims to debut a 20+ terabyte drive based on HAMR in 2020, and Western Digital promises MAMR drives that will hold roughly 16 TB later this year. Western Digital expects to scale up to MAMR drives with 40 TB of capacity by 2025, while Seagate believes it can achieve similar capacities through HAMR.

The need for new approaches in hard disk read and write technologies is obvious: Make the tiny grains (magnetic material) on the disk platter stable at room temperature. Stability means that these grains, which currently are just 7 nanometers wide, should not flip spontaneously, resulting to wiping out the data they hold. To prevent such erasures, manufacturers have begun to use new materials, such as iron-platinum alloys, to make disks with magnetically “harder” grains that will not randomly flip. But that change also makes it impossible for traditional read/write heads to flip a grain, because they simply cannot generate a strong enough magnetic field and focus it on such a small area.

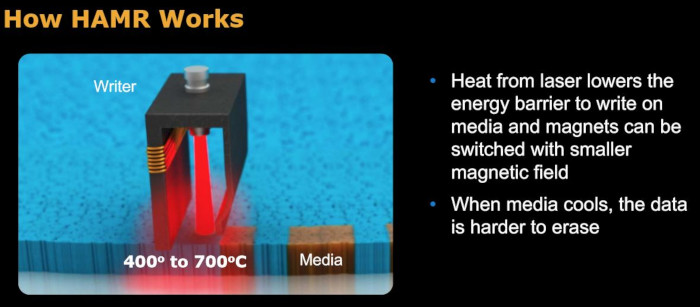

Here is where HAMR and MAMR approaches kick in. Both technologies apply energy into the targeted grains on a hard disk and temporarily flip their magnetic orientation with an external magnetic field of practical magnitude. As soon as the energy dissipates, the grains regain their immunity to spontaneous room-temperature flips.

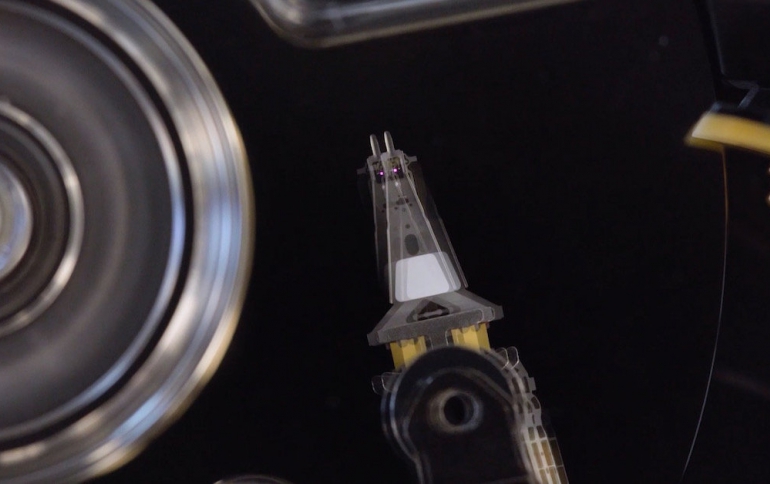

Seagate has chosen to use a laser’s light narrow enough to focus its energy on an area narrower than the wavelength of the light beam itself. By making the laser's spot smaller, adjacent grains won't flip. Seagate's researchers built a head loaded with an infrared laser and directed a fraction of the light it produced to a tiny metal plate that measures just 200 nm across. Seagate researchers call this plate the “lollipop” because of its size. When light reaches the lollipop, it excites surface plasmons, which are bunches of electrons of oscillating density that can arise on the surface of most metals. These plasmons pass energy to a small peg of the “lollipop” , whose peculiar shape provides the path of least resistance for the energy to leave the lollipop. Once at the peg, the plasmons discharge energy into a narrow sliver of the disk. This electrical discharge heats the disk, and for a very brief period, the magnetization of the grains in a small region can be reoriented by a field produced by the read-write head—before a heat-sink layer built into the disk whisks the energy away.

However, this scheme didn't work well in the first implementations of HAMR in hard drives, since the gold peg of the lollipop kept melting. To solve this issue, Seagate's team redesigned the head to better direct excess light and heat away from the lollipop, switched to a new material, and made the lollipop thicker. Currently, Seagate clams that a HAMR head can write petabytes of data without failing, and that the company has built more than 50,000 HAMR drives.

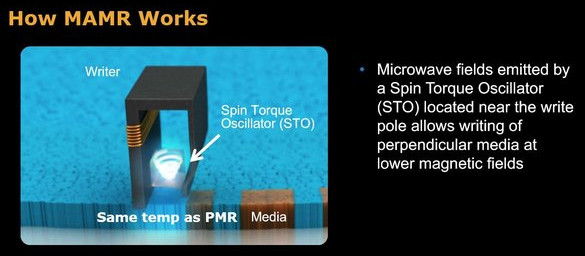

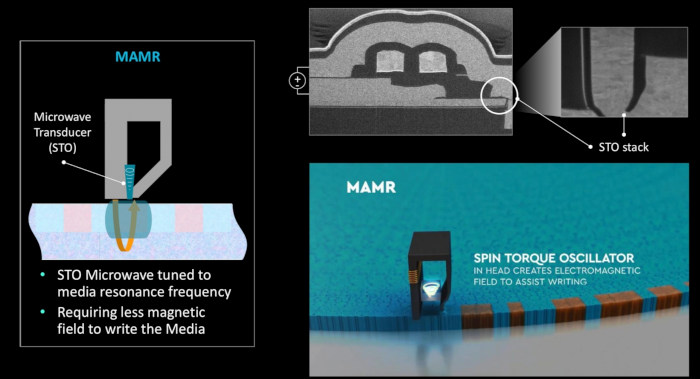

Western Digital chose to advance and promote MAMR. In this approach, the read/write head includes a device called a spin-torque oscillator, which consists of at least two magnetic layers. As a direct current passes through the first, the spins of the electrons become polarized. Then, the electrons pass through the second layer, which is deliberately built to have an opposite magnetic alignment. During this second stage, the spin-polarized incoming electrons influence those within the magnetic layer, shifting its magnetization slightly before passing through to the other side.

The interaction creates a wobble in the magnetic moments of electrons within the second layer. This process emits a microwave field, which can be tuned to the resonant frequency of the magnetic material coating the hard disk—about 15 to 20 gigahertz. As this field oscillates, it stirs up a similar wobble in a narrow slice of grains on the disk below, making them easier to flip. Researchers believe that a spin-torque oscillator could generate frequencies up to 40 GHz, allowing MAMR to support four or five times the capacity of today’s drives.

As a note, Seagate has not abandoned the MAMR approach, and Western Digital also owns HAMR technology, despite what the companies have chosen to pursuit and promote first.

Ultimately, both hard disk makers Digital will need to persuade customers that their technology is superior, mainly in terms of reliability. They will have to orchestrate their respective approaches in order to be reliably produced on existing manufacturing lines in large volumes.