Intel CEO Says 7nm Chips Coming in 2021

Intel Chief Executive Officer Bob Swan said on Wednesday the chipmaker would produce and launch its 7 nanometer (nm) chip products in 2021.

The company plans to launch 10nm chips for high-end personal computers later this year, and for servers early next year.

Swan made the annoucnement during Intel's 2019 investor meeting held at Intel headquarters in Santa Clara.

He added the company sees both revenue and earnings per share growing in the “single digit” percentage range over the next three years, with flat PC chip sales offset by “double digit” percentage revenue growth in data center chips.

Intel CEO also said operating margins would remain relatively steady at 32 percent, but that gross margins would decline as the company ramps up its 10-nanometer chipmaking technology.

Swan said demand for the analysis, transmission and storage of data is growing at a faster rate than at any time in history.

“We are very focused on leading technology inflections that will accelerate and create demand for data – AI, 5G and autonomous,” Swan said. “We believe in an expanded market opportunity we can play a bigger role in the success of our customers. Our emphasis is on improving execution, accelerating innovation and evolving our strong culture while making disciplined investments in pursuit of profitable growth.”

With a range of 10nm-based products planned for 2019 and 2020, Intel’s 7nm process is also well underway. Intel’s first 7nm-based product, an Intel Xe Architecture-based GP-GPU for data center artificial intelligence (AI) and high-performance computing (HPC), is expected to launch in 2021.

Dr. Murthy Renduchintala, Intel’s chief engineering officer and group president of the Technology, Systems Architecture and Client Group announced that Intel will start shipping its volume 10nm client processor in June and shared first details on the company’s 7nm process technology.

Intel’s first volume 10nm processor, a mobile PC platform code-named “Ice Lake,” will begin shipping in June. Renduchintala said that the Ice Lake platform will take full advantage of 10nm along with "architecture innovations." It is expected to deliver approximately 3 times faster wireless speeds, 2 times faster video transcode speeds, 2 times faster graphics performance, and 2.5 to 3 times faster artificial intelligence (AI) performance over previous generation products. As announced, Ice Lake-based devices from Intel OEM partners will be on shelves for the 2019 holiday season. Intel also plans to launch multiple 10nm products across the portfolio through 2019 and 2020, including additional CPUs for client and server, the Intel Agilex family of FPGAs, the Intel Nervana NNP-I (AI inference processor), a general-purpose GPU and the “Snow Ridge” 5G-ready network system-on-chip (SOC).

Building on a model proven with 14nm that included optimizations in 14+ nm and 14++ nm, the company will drive sustained process advancement between nodes and within a node. The company plans to deliver performance and scaling at the beginning of a node, plus another performance improvement within the node through multiple intra-node optimizations within the technology generation.

Renduchintala also provided first updates on Intel’s 7nm process technology that will deliver 2 times scaling and is expected to provide approximately 20 percent increase in performance per watt with a 4 times reduction in design rule complexity. It will mark the company’s first commercial use of extreme ultraviolet (EUV) lithography.

The lead 7nm product is expected to be an Intel Xe architecture-based, general-purpose GPU for data center AI and high-performance computing. It will embody a heterogeneous approach to product construction using advanced packaging technology. On the heels of Intel’s first discrete GPU coming in 2020, the 7nm general purpose GPU is expected to launch in 2021.

As with prior nodes, Intel plans to release intra-node optimizations at 7 nm. The company is targeting a 7-nm+ process in 2022 and a 7-nm++ in 2023.

Intel has struggled with delays on its 10nm chip making technology, losing its lead in making the smallest chip features to rival Taiwan Semiconductor Manufacturing Co Ltd (TSMC). Difficulties with ramping up the yield of 10-nm to acceptable production levels have caused a lengthy delay in the rollout of the chips, which were initially targeted for release in 2016. Intel's delays at 10-nm have contributed to the company losing some market share to longtime PC processor rival AMD, which plans to begin shipping 7-nm chips later this year.

Meanwhile, Taiwan Semiconductor Manufacturing Company (TSMC) is said to be on track to move 5nm process technology to volume production in 2020, and reportedly has plans to roll out an enhanced version of the process a year later.

Dubbed N5+, namely 5nm Plus, the process node will feature both performance and power consumption advances, according to a recent Chinese-language Commercial Times report. The foundry is expected to move N5+ to risk production in the first quarter of 2020, the report said, without citing its source.

TSMC has already kicked off risk production of 5nm chips, said the report, adding that the process is expected to be ready for commercial production in the second quarter of 2020 when the phase-one facility of the foundry's new Fab 18 comes online.

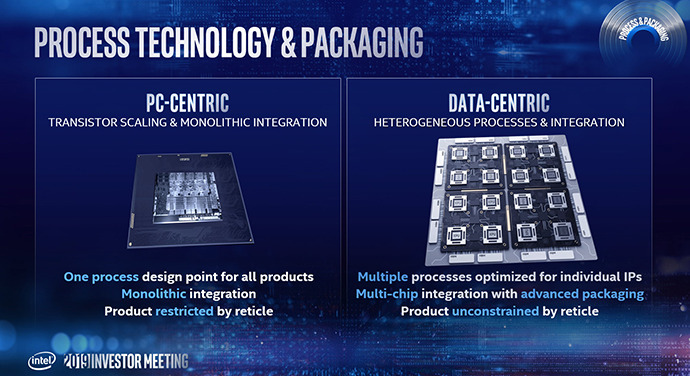

Renduchintala also previewed new chip designs that leverage advanced 2D and 3D packaging technology to integrate multiple intellectual property (IP), each on its own optimized process technology, into a single package. The heterogeneous approach allows new process technologies to be leveraged earlier by interconnecting multiple smaller chiplets, and larger platforms to be built with unprecedented levels of performance when compared to non-monolithic alternatives.

Renduchintala unveiled the performance gains that resulted from development of the client platform code-named “Lakefield”. The approach is symbolic of the strategic shift in the company’s design and engineering model that underpins Intel’s future product roadmaps. To meet customer specifications, a breadth of technical innovations including a hybrid CPU architecture and Foveros 3D packaging technology were used to meet always-on, always-connected and form-factor requirements while simultaneously delivering to power and performance targets. Lakefield is projected to deliver approximately 10 times SOC standby power improvement and 1.5 to 2 times active SOC power improvement relative to 14nm predecessors, 2 times graphics performance increases, and 2 times reduction in printed-circuit-board (PCB) area, enabling OEMs to have more flexibility for thin and light form factor designs.

Renduchintala also said Intel has redefined its product innovation model for the data-centric era of computing, which “requires workload-optimized platforms and effortless customer and developer innovation.” He shared expected performance gains resulting from a combination of technical innovations across six pillars – process and packaging, architecture, memory, interconnect, security and software – giving insight into the design and engineering model steering the company’s product development.

“While process and CPU leadership remain fundamentally important, an extraordinary rate of innovation is required across a combination of foundational building blocks that also include architecture, memory, interconnect, security and software, to take full advantage of the opportunities created by the explosion of data,” Renduchintala said. “Only Intel has the R&D, talent, world-class portfolio of technologies and intellectual property to deliver leadership products across the breadth of architectures and workloads required to meet the demands of the expanding data-centric market.”

AI is a fast-growing workload, especially in the data center. Intel estimates the TAM for AI silicon in the data center is growing at a 25 percent CAGR and is expected to reach $10 billion by 2023. In 2018, Intel captured roughly 40 percent of the current estimated $4 billion data center AI silicon opportunity, achieving $1.7 billion in AI revenue. The company aims to expand its prospects with a range of AI-optimized products including the new 2nd Gen Intel Xeon Scalable processor, programmable solutions and purpose-built chips like the forthcoming Intel Nervana Neural Network Processors.

Autonomous driving is another major tech inflection that Intel is poised to lead by building on Mobileye’s strong momentum in driver-assistance systems (ADAS). Mobileye CEO Professor Amnon Shashua told investors that in addition to providing the technology to safely power autonomous cars, Mobileye is pursuing new revenue streams including the monetization of mapping dataand mobility-as-a-service. Shashua said, “Transportation as a service, enabled by robotaxis, is a game changer for mobility, and I’m here to tell you that we plan to go all in on the global robotaxi opportunity.”