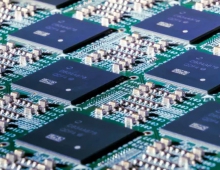

New NAND Flash Technology Doubles Capacity

msystems announced its x4 technology, a new technology that is claimed to offer more economic NAND flash manufacturing with no changes to manufacturing processes.

The x4 technology enables the storage of 4 bits of data per cell on nearly the same die size as 2 bits, previously considered to be a practical and physical impossibility. x4 NAND components, likely to be mass produced during 2007, are to be comprised of the first-ever 4-bit/cell NAND flash media and a x4 technology controller.

The technology is expected to offer NAND flash manufacturers a 30% cost saving in comparison with the most advanced 2-bit/cell multi-level cell (MLC) NAND flash wafers manufactured to date through equivalent lithography. This is accomplished by doubling bit density in comparison with such MLC NAND flash, and quadrupling it when compared with single-level cell (SLC) NAND flash.

Since higher densities could lead to more errors, msystems developed a new error correction algorithm, making 4-bit/cell flash technology possible. The x4 technology applies msystems? advanced error correction code (ECC), using new methodologies and algorithms to reduce the error rate to bring 4 bits per cell flash reliability within the required industry standards, optimize performance, minimize required silicon redundancy and minimize power consumption.

Furthermore, as msystems? x4 technology requires no changes to manufacturing processes, it stands to increase fab profitability.

NAND components are expected to target consumer electronics devices, such as digital audio (MP3) players, consumer solid state drives (SSDs), portable media players, digital video cameras, GPS devices, multimedia and music handsets, memory cards and USB flash drives.

Several x4 technology partnerships are currently being evaluated by msystems, and are likely to lead to mass production of x4 NAND components during 2007.

The technology is expected to offer NAND flash manufacturers a 30% cost saving in comparison with the most advanced 2-bit/cell multi-level cell (MLC) NAND flash wafers manufactured to date through equivalent lithography. This is accomplished by doubling bit density in comparison with such MLC NAND flash, and quadrupling it when compared with single-level cell (SLC) NAND flash.

Since higher densities could lead to more errors, msystems developed a new error correction algorithm, making 4-bit/cell flash technology possible. The x4 technology applies msystems? advanced error correction code (ECC), using new methodologies and algorithms to reduce the error rate to bring 4 bits per cell flash reliability within the required industry standards, optimize performance, minimize required silicon redundancy and minimize power consumption.

Furthermore, as msystems? x4 technology requires no changes to manufacturing processes, it stands to increase fab profitability.

NAND components are expected to target consumer electronics devices, such as digital audio (MP3) players, consumer solid state drives (SSDs), portable media players, digital video cameras, GPS devices, multimedia and music handsets, memory cards and USB flash drives.

Several x4 technology partnerships are currently being evaluated by msystems, and are likely to lead to mass production of x4 NAND components during 2007.