STEC CellCare Technology Delivers Boost in 24 nm MLC NAND Flash Memory Endurance

STEC has validated its CellCare Technology's ability to extend the endurance of 24 nm consumer-grade multi-level cell (cMLC) NAND flash memory to 40,000 program/erase cycles.

This represents an increase of greater than 13 times the manufacturer's specified endurance metric of 3,000 program/erase cycles.

This is a significant advancement in one of the company's core technologies, as it provides for the development of a new generation of STEC's enterprise-class SSDs that utilizes low-cost cMLC NAND chips, while still achieving 10 full capacity random writes to the drive each day for five years, and data retention for three months (at 40°C) - all with no degradation in performance. This equates to approximately 7.3 petabytes (PB) of data being written to a 400 GB SSD over the life of the drive.

"The results of the 24nm cMLC endurance testing, performed at our San Diego R&D center, are testimony that the solid flash management algorithms and digital signal processing/ error correction code within our patented CellCare Technology bring true enterprise-class capabilities to consumer-grade flash memory," said Pablo Ziperovich, STEC's Vice President, Flash Channel Development. "We have now tested the use of lower-cost 24 nm cMLC NAND with our CellCare Technology to withstand the rigorous workload environments of enterprise storage applicationsspecifically, to provide for 40,000 program/erase cycles."

After applying STEC's CellCare Technology in combination with its fourth-generation ASIC-based SSD controller, STEC engineers performed a series of JEDEC - standard tests, including a program/erase endurance and data retention stress test; a stress-test-driven qualification of integrated circuits; and a SSD requirements and endurance test.

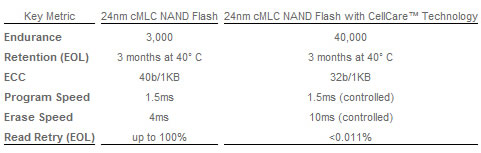

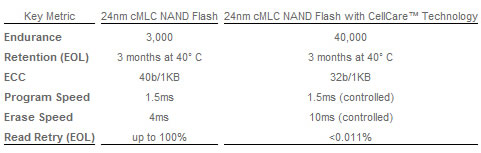

Results of the endurance testing are outlined in the table below:

CellCare Technology is a proprietary combination of hardware and firmware working together to improve MLC flash performance and endurance throughout the life of the drive. Key endurance-extending features of this patented technology include:

- Flash parameter tracking per die, which delivers reduced and controlled wear;

- Flash management through the lifetime, which delivers reduced wear, controlled performance, improved performance, and lower write/read latency;

- Advanced error correction with digital signal processing to improve data reliability and require a minimum of re-reads.

CellCare Technology is embedded in STEC's full line of MLC NAND-based enterprise-class solid-state solutions, including its PCIe solid-state accelerators, ZeusIOPS SAS SSDs, and MACH16 SATA SSDs. STEC's 24 nm cMLC NAND flash-based SSDs are currently in development and testing, with production anticipated for later this year.

This is a significant advancement in one of the company's core technologies, as it provides for the development of a new generation of STEC's enterprise-class SSDs that utilizes low-cost cMLC NAND chips, while still achieving 10 full capacity random writes to the drive each day for five years, and data retention for three months (at 40°C) - all with no degradation in performance. This equates to approximately 7.3 petabytes (PB) of data being written to a 400 GB SSD over the life of the drive.

"The results of the 24nm cMLC endurance testing, performed at our San Diego R&D center, are testimony that the solid flash management algorithms and digital signal processing/ error correction code within our patented CellCare Technology bring true enterprise-class capabilities to consumer-grade flash memory," said Pablo Ziperovich, STEC's Vice President, Flash Channel Development. "We have now tested the use of lower-cost 24 nm cMLC NAND with our CellCare Technology to withstand the rigorous workload environments of enterprise storage applicationsspecifically, to provide for 40,000 program/erase cycles."

After applying STEC's CellCare Technology in combination with its fourth-generation ASIC-based SSD controller, STEC engineers performed a series of JEDEC - standard tests, including a program/erase endurance and data retention stress test; a stress-test-driven qualification of integrated circuits; and a SSD requirements and endurance test.

Results of the endurance testing are outlined in the table below:

CellCare Technology is a proprietary combination of hardware and firmware working together to improve MLC flash performance and endurance throughout the life of the drive. Key endurance-extending features of this patented technology include:

- Flash parameter tracking per die, which delivers reduced and controlled wear;

- Flash management through the lifetime, which delivers reduced wear, controlled performance, improved performance, and lower write/read latency;

- Advanced error correction with digital signal processing to improve data reliability and require a minimum of re-reads.

CellCare Technology is embedded in STEC's full line of MLC NAND-based enterprise-class solid-state solutions, including its PCIe solid-state accelerators, ZeusIOPS SAS SSDs, and MACH16 SATA SSDs. STEC's 24 nm cMLC NAND flash-based SSDs are currently in development and testing, with production anticipated for later this year.