Greenliant microSD ArmourDrive Cards

1. Introduction

MicroSD storage is everywhere; from mobile devices to cameras and industrial systems, the microSD format has become an industry standard. Greenliant is a Silicon Valley, California-based company that designs and manufactures its own line of solid state drives (SSDs) and memory cards, and today we will examine two products from their lineup, industrial temperature (-40°C to 85°C) 64GB and wide temperature (-25°C to 85°C) 1TB microSD cards that promise high performance and strong endurance for even the most demanding tasks.

The microSD removable miniaturized Secure Digital flash memory cards were originally named T-Flash or TF, abbreviations of TransFlash. TransFlash and microSD cards are functionally identical allowing either to operate in devices made for the other. At CTIA Wireless 2005, the SDA announced the small microSD form factor along with SDHC secure digital high capacity formatting in excess of 2 GB with a minimum sustained read and write speed of 17.6 Mbit/s. The SDA approved the final microSD specification on July 13, 2005. Initially, microSD cards were available in capacities of 32, 64, and 128 MB.

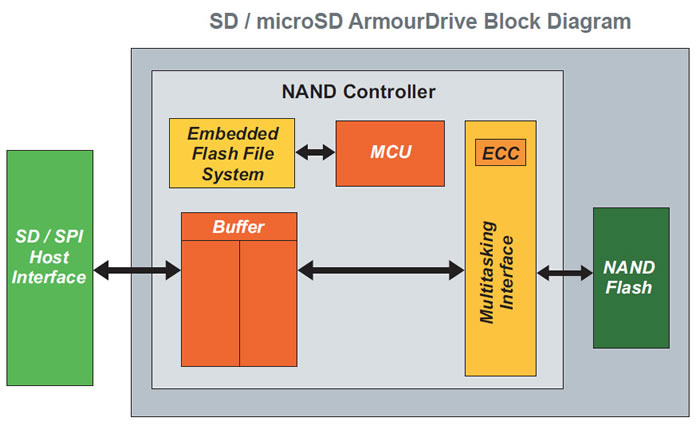

Greenliant’s SD / microSD ArmourDrive family (93 Series) consists of high-reliability, industrial flash memory cards in a wide selection of capacities and endurance specifications with 1-bit-per-cell (SLC), 3-bit-per-cell (TLC) or 4-bit-per-cell (QLC) 3D NAND configurations. Operating at extreme temperatures, these products are ideal for applications requiring removable data storage able to withstand demanding environments with high workloads.

The 93 Series product family implements advanced NAND flash management technology to preserve data integrity and extend memory card lifespan. Built in the standard SD and microSD card form factors, and backed by Greenliant’s technical support, SD and microSD ArmourDrive memory cards give industrial, medical, gaming, video and imaging customers added flexibility when selecting reliable, hot-swappable solid state storage for space-constrained, embedded systems.

Applications

— Transportation

— Vending

— Agriculture

— Industrial PC

— Navigation

— Infotainment

— Aviation

— Point-of-sales

— Security / Surveillance

— Industrial automation & control

— Data logger

— Healthcare

— Test & measurement

— Networking

— Handheld scanner

— Professional video / photo

Key Features

microSD Form Factor and Interface (15 x 11 x 1.0 mm)

- Compliant with SD Specification Version 6.10

- Supports SD and SPI protocols

High Performance

- Sequential Read / Write performance up to

100MB/s / 85MB/s

- Bus speed mode up to UHS-I 104

- Class 10 Speed performance rating

Energy Efficient

- 3.3V low power supply

- Active Mode less than 405mA

- Standby Mode less than 1mA

Advanced Flash Management

- Dynamic and static wear leveling algorithms

maximize product lifespan

- Replaces bad blocks with spare blocks in the NAND flash to prevent uncorrectable errors

Built-in ECC

- Uses advanced bit error detection and

correction optimized for 3D NAND

SSD Lifespan Monitoring

- Supports SMART command-based alerts

indicating the remaining useful product life

Data Security

- CPRM support (optional)

- Password protection (optional)

High Reliability

- MTBF: 3M hours (SLC/TLC); 2M hours (QLC)

- Shock (1500G) and vibration (20G) resistant

- Waterproof (water depth up to 1000mm)

Power Interrupt Data Protection

- Helps prevent data corruption during

unexpected power failure events

Wide Range of Capacities

- EX Series (SLC): 8 GB - 64 GB

- PX Series (TLC): 32 GB - 256 GB

- QX Series (QLC): 256 GB - 1 TB

Operating/Temperature Range

- Industrial: -40°C to +85°C

- Wide: -25°C to +85°C

The 93 Series come either in SD or microSD format with the following NAND flash storage categories:

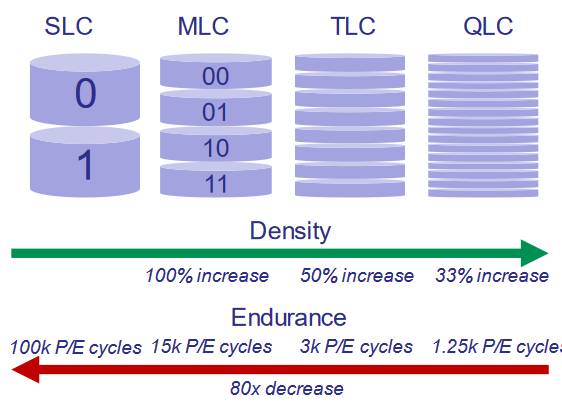

Image Credit: IBM Research, Flash Memory Summit

SLC NAND: Highest endurance - Con: Expensive

Single-level cell (SLC) NAND stores 1 bit of information per cell. The cell stores either a 0 or 1 and as a result, the data can be written and retrieved faster. SLC provides the highest endurance up to 100,000 P/E cycles and superior data retention, so it will last longer than the other types of NAND. However, its low data density makes SLC the most expensive type of NAND and therefore not commonly used in consumer products. It is typically used for industrial and networking applications that require superior endurance and long-term reliability.

TLC NAND: Cheaper and higher capacities - Con: Low endurance

Triple-level cell (TLC) NAND stores 3 bits per cell. By adding more bits per cell, this reduces the cost and increases the capacity. However, this has negative effects on endurance, which s typically at 3,000 P/E cycles for 3D TLC NAND. Many consumer products will use TLC as it is a cheaper option.

QLC NAND: Cheapest and highest capacities - Con: Lowest endurance

Quad-level cell (QLC) NAND stores 4 bits per cell, further increasing capacity and reducing cost. Endurance is reduced significantly, though, to 1,000 P/E cycles or less. For applications that don’t require high endurance, QLC is attractive because of lower cost.

In the last ten years, 3D NAND has been one of the biggest innovations in the flash market. Flash manufacturers developed 3D NAND to correct the problems they were facing with scaling down 2D NAND in order to achieve higher densities at a lower cost. In 2D NAND, the cells that store the data are placed horizontally, side by side. This means that the amount of space that the cells can be placed onto is limited and trying to make the cells smaller reduces their reliability. Therefore, NAND manufacturers decided to stack the cells in a different dimension, which led to 3D NAND where the cells are stacked vertically. The higher memory density allows for higher storage capacities without the huge price increase. 3D NAND also provides better endurance and lower power consumption.