Hitachi Promises 2-Terabyte Hard Drive by Decade End

Celebrating the 50-year anniversary since the birth of the hard drive, Hitachi is also celebrating an areal density achievement of 345 gigabits per square inch (Gbits/sq. in.) using perpendicular magnetic recording (PMR) technology.

This areal density, demonstrated in laboratory testing, represents an increase of more than two-and-a-half times the areal density of today's highest-capacity products.

By 2009, Hitachi predicts that 345 Gbits/sq. in. would result in a two-terabyte (TB) 3.5-inch desktop drive, a 400-gigabyte (GB) 2.5-inch notebook drive or a 200-GB 1.8-inch drive. In the first half of 2007, Hitachi expects to bring hard drive areal density half way to the 345 Gbits/sq. in. mark with a 1-TB 3.5-inch product.

While 345 Gbits/sq. in. is within grasp in the next two to three years, researchers at Hitachi anticipate that extensions to PMR technology will take hard drive advancements out beyond the next two decades, using ever more complex and sophisticated means such as patterned media and thermally-assisted recording. With these technologies, Hitachi predicts that continued areal density advancements would be possible ten plus years into the future. For example, in approximately 2016, 4 terabits per square inch (Tbits/sq. in.) areal density would enable a 25-TB 3.5-inch drive. Beyond that, Hitachi anticipates as much as 100 Tbits/sq. in. areal density will be possible, which would enable a 0.65-petabyte 3.5-inch drive.

"We are very optimistic about the future for Hitachi and the hard disk drive industry with research on these technologies strongly underway," said Hiroaki Nakanishi, CEO, Hitachi Global Storage Technologies. "The inventors of the original RAMAC could not have seen five decades of innovation in 1956, but here we are today celebrating its Golden Anniversary. With continued research investment, we look forward to celebrating 75 years -- the Diamond Anniversary -- of hard drive technology."

With PMR technology rolled out in high-volume production this year -- appropriately on the 50th anniversary of the hard drive -- researchers are looking at overcoming the next obstacles to advancing hard drive technology. The major challenge that hard disk drive designers are facing in increasing data densities is that the magnetic grains on the disk that store the data must become smaller and will eventually become too small to be thermally stable at room temperature. Patterned media and thermally-assisted recording are solutions to this problem.

Today, roughly 100 magnetic grains make up a single bit of data. With patterned media, researchers are creating isolated magnetic islands with one magnetic grain representing a bit of data. By using fewer magnetic grains, patterned media allows more bits of data per square inch of disk space while maintaining thermal stability.

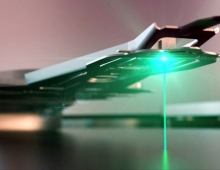

Rather than using fewer grains to represent a bit of data, thermally-assisted recording allows magnetic grains to be smaller while resisting thermal fluctuations at room temperature. As its name suggests, thermally-assisted recording uses a laser to heat up the media while the magnetic head is writing the smaller bits of data. This enables the use of media that is stable at room temperature with the very small magnetic grains required for high-density storage.

Hitachi researchers predict that patterned media technology could ship in products as early as 2010. They believe that thermally-assisted recording would be combined with patterned media technology several years later when patterning alone is insufficient to sustain progress.

By 2009, Hitachi predicts that 345 Gbits/sq. in. would result in a two-terabyte (TB) 3.5-inch desktop drive, a 400-gigabyte (GB) 2.5-inch notebook drive or a 200-GB 1.8-inch drive. In the first half of 2007, Hitachi expects to bring hard drive areal density half way to the 345 Gbits/sq. in. mark with a 1-TB 3.5-inch product.

While 345 Gbits/sq. in. is within grasp in the next two to three years, researchers at Hitachi anticipate that extensions to PMR technology will take hard drive advancements out beyond the next two decades, using ever more complex and sophisticated means such as patterned media and thermally-assisted recording. With these technologies, Hitachi predicts that continued areal density advancements would be possible ten plus years into the future. For example, in approximately 2016, 4 terabits per square inch (Tbits/sq. in.) areal density would enable a 25-TB 3.5-inch drive. Beyond that, Hitachi anticipates as much as 100 Tbits/sq. in. areal density will be possible, which would enable a 0.65-petabyte 3.5-inch drive.

"We are very optimistic about the future for Hitachi and the hard disk drive industry with research on these technologies strongly underway," said Hiroaki Nakanishi, CEO, Hitachi Global Storage Technologies. "The inventors of the original RAMAC could not have seen five decades of innovation in 1956, but here we are today celebrating its Golden Anniversary. With continued research investment, we look forward to celebrating 75 years -- the Diamond Anniversary -- of hard drive technology."

With PMR technology rolled out in high-volume production this year -- appropriately on the 50th anniversary of the hard drive -- researchers are looking at overcoming the next obstacles to advancing hard drive technology. The major challenge that hard disk drive designers are facing in increasing data densities is that the magnetic grains on the disk that store the data must become smaller and will eventually become too small to be thermally stable at room temperature. Patterned media and thermally-assisted recording are solutions to this problem.

Today, roughly 100 magnetic grains make up a single bit of data. With patterned media, researchers are creating isolated magnetic islands with one magnetic grain representing a bit of data. By using fewer magnetic grains, patterned media allows more bits of data per square inch of disk space while maintaining thermal stability.

Rather than using fewer grains to represent a bit of data, thermally-assisted recording allows magnetic grains to be smaller while resisting thermal fluctuations at room temperature. As its name suggests, thermally-assisted recording uses a laser to heat up the media while the magnetic head is writing the smaller bits of data. This enables the use of media that is stable at room temperature with the very small magnetic grains required for high-density storage.

Hitachi researchers predict that patterned media technology could ship in products as early as 2010. They believe that thermally-assisted recording would be combined with patterned media technology several years later when patterning alone is insufficient to sustain progress.