ATP’s New High-Endurance, Low-Latency SD/microSD Cards Built for Dashcams, DVRs Offer Over 109K Hours of Continuous Video Recor

ATP Electronics, the global leader in specialized storage and memory solutions, introduces its new 3D triple level cell (TLC) S750/S650 Series SD and microSD memory cards built for the rigors of non-stop video recording. They meet the high endurance, low latency, and built-to-last data storage requirements of dashcams and digital video recorders (DVRs), as well as surveillance systems, autonomous vehicles, and other write-intensive applications.

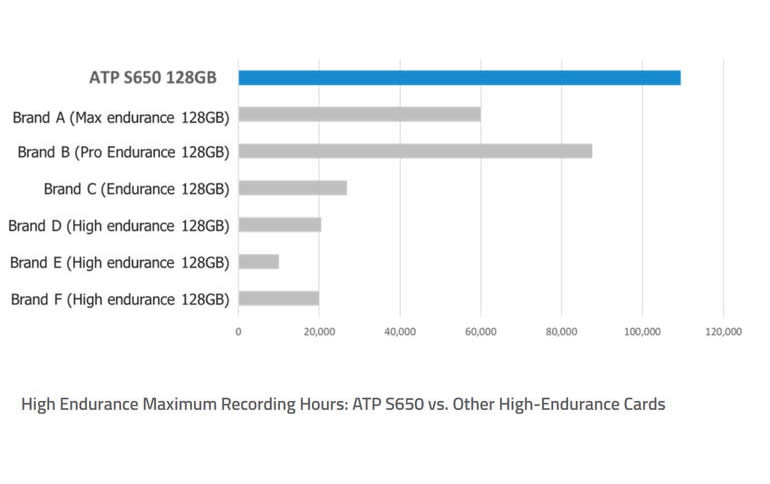

High Endurance Over 109K Hours1 of Recording Time in Native TLC

Video evidence can prove critical in many scenarios; hence, it is very important for SD/microSD cards to record non-stop without compromising image quality and integrity. The S650 Series can record Full HD videos continuously up to 109,401 hours — far longer than similar cards marketed as “high endurance.” The S650 Series is based on 5K program/erase (P/E) cycles, which translate to 1.6X higher endurance than typical memory cards with 3K P/E cycles. The S750 Series, configured as pseudo single-level cell (pSLC) is based on 60K P/E cycles, while typical pSLC memory cards are rated for around 20K to 30K P/E cycles.

Low Latency: Ready to Record in <1 Second, Writes 50% Faster

After power on, drive recorders may have to wait a few seconds to be ready for recording. The time between the first read command and the first write command from host is the "response time." ATP S650 and S750 Series cards take less than 1 second response time while normal cards may take 7 to 12 seconds based on real tests on a DVR at room temperature. While recording 16 MB data sequentially, ATP S650 cards take less than 0.1 second, saving 50% of writing time compared with consumer-rated cards and enabling high-speed backup without data loss.

Own HW/FW Design Features Offer Precise Reliability

As a true manufacturer with its own hardware/firmware capability, ATP can adjust to a variety of usages to fulfill customers’ specific application requirements and conditions. Based on customers' applications, ATP does its best to meet the requirements by unique FW and HW design.

Auto-Read Calibration (ARC). Over time and with constant use, NAND flash memory cells degrade, causing voltage shifts that increase bit error rates (BER). When the normal Read Retry function is not enough to recover the errors, a more precise "Auto Read Calibration" (ARC) is applied to assure data integrity at extreme temperature or degraded NAND cells.

ATP Methodology for Advanced Card Analysis. ATP memory cards are IP67/IP57-certified and manufactured using System-in-Package (SiP) wafer/die process, making it difficult to do component analysis compared to SMT (surface- mount technology) process. ATP’s uniquely designed substrate and debug tool make this mission "possible."

ATP-Developed Hardware Design - Substrate with reserved testing pin is available for future component analysis.

Solder Mask Removal by Laser – Precise and efficient method to remove solder mask so as to reach the reserved testing pins on the substrate.

ATP’s Own Customized Debug Tool - This is connected to the HW reserved testing pin and then linked to the SW analysis system.

For further information on ATP’s advanced card analysis methodology, please go to: https://www.youtube.com/watch?v=89Lm_eC3mSU