ATP TLC SSDs Match MLC Endurance with 66% Higher Endurance

Manufactured using a new die package, the Serial ATA solid state drives (SATA SSDs) deliver 66% higher endurance in native TLC mode and 50% higher in pseudo single level cell (pSLC) mode, making them on par with drives built on multi-level cell (MLC) and SLC flash, respectively.

The new SSDs come in M.2 2280 and 2242 as well as 2.5" and mSATA form factors. A750Pi/A650Si SSDs support industrial temperature (I-Temp) ranges from -40°C to 85°C to perform reliably even when operating under extreme and harsh conditions. A650Sc SSDs can support commercial operating temperatures (C-Temp) from 0°C to 70°C. A650Si/Sc with native TLC NAND flash have capacities from 120 to 1920 GB, while A750Pi drives configured in pSLC offer 80 to 640 GB. Depending on project and specific part number request, ATP's new SATA embedded SSDs are also available as self-encrypting drives (SEDs) featuring AES-256 encryption and Opal TCG 2.0-compliant security.

"Industries were initially hesitant to use TLC for applications that required reliable performance and long endurance. Conscious of TLC limitations, ATP worked hard to make it equivalent to, or even better than its pricier MLC and SLC counterparts, minus the hefty cost of ownership," said Chris Lien, Head of ATP's Embedded SSD Business Unit. "As an industry leader, we did not rest until we have exhausted all possible means and resources to deliver these premium offerings. We are proud to say that our 3D TLC products are exceptionally competitive, thanks to a new die package design, exhaustive testing and validation, superior power loss protection, and other features. ATP's advanced pSLC technology extends the general endurance to more than 10 times that of TLC-based products. It also improves the sustained write performance and reliability of the drive, making the drives suitable for write-intensive applications."

Reliability Testing and Validation: Setting ATP SSDs a Cut Above the Rest

Reliability testing is an important cornerstone in the ATP manufacturing process. ATP's embedded SATA SSDs go through standard as well as customizable testing depending on customer requests and application-specific requirements.

Four-Corner, Temperature Cycling, and Power Cycling Tests demonstrate that the SSDs can still perform reliably and are able to handle stored data without data miscompare even under harsh conditions.

End-of-Life Validation Test makes sure that ATP SSDs perform reliably and maintain data integrity over their life span (and even beyond) as required.

PCBA Solderability Validation makes sure that components on the printed circuit board assembly (PCBA) are effectively bonded to form reliable mechanical and electrical connections.

Reliability Demonstration Test (RDT) validates the mean time between failures (MTBF) rating of the drive through actual drive-level testing instead of relying on reliability prediction systems.

Breakthrough MCU Design for Enhanced Power Management and PLP Capabilities

The latest A750Pi/A650Si Series SATA SSDs feature a new design of the power loss protection (PLP) array, which utilizes a new power management IC (PMIC) and new firmware-programmable MCU (microcontroller unit). The new MCU design allows the PLP array to perform intelligently in various temperatures, power glitches and charge states.

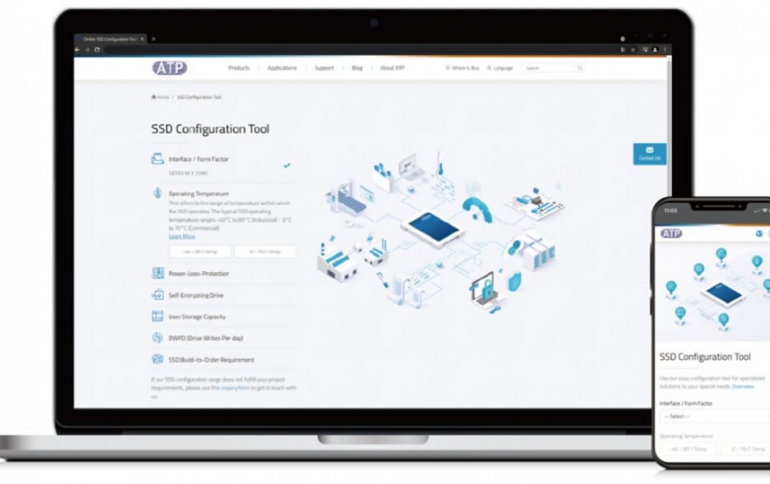

ATP SSD Configuration Tool

The ATP SSD Configuration Tool is available to make sure that ATP storage solutions meet customers' requirements. Customers simply need to input their desired specifications, such as form factor, capacity, operating temperature, and endurance (in terabytes written or TBW). They also have the option to configure based on a two-year or five-year workload. The tool can help assess if a standard product is available for purchase, or if customization is required. To access the ATP SSD Configuration Tool, click https://www.atpinc.com/ssd-configuration