Sony Develops Mass Production Technology For More Secure Holograms

Sony Disc and Digital Solutions (SDAD) today announced the development of new mass production technology which adds an additional layer of security to Lippmann holograms by recording individually distinct identification codes.

There has been an increase in the production and sales of counterfeit products and illegal imitations - in addition to credit cards, ID cards and bank notes - which violate intellectual property rights. In reaction to the progression of illegal fabrication technology, the demand for highly secure hologram technology, with faster and more accurate authentication has rapidly increased.

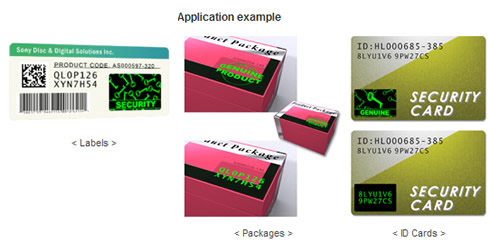

Lippmann holograms are used in order to protect IP. An optical interference fringe is formed by refractive index modulation in the special photo-sensitive material. When white-light is illuminated onto the photo-sensitive material, a holographic image appears through a diffractive phenomenon. Such conventional Lippmann holograms were mass-produced by contact copy in which the master forms of these holograms were optically replicated. This conventional method allows for the simple mass production of identical holograms, but does not allow for the mass production of holograms containing individually variable information. Sony has added an extra layer of protection by adding individually distinct identification codes in Lippmann holograms. The company claims that these are are extremely resistant to counterfeiting and forgery, and are most suitable for credit cards, smart IC cards and authentication stickers. SDAD plans to mass produce Lippmann holograms with up to 21 encrypted digits in a single hologram.

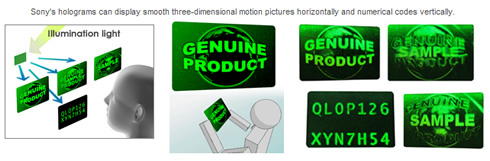

SDAD will use master-forms of holograms which are made by holographic stereogram technology with digital image processing which records more than one hundred images onto a single hologram sheet. Therefore it can store flying logos (three-dimensional computer graphics) and moving animation.

Lippmann holograms can be applied as advertising and marketing tools because it can display photographic images, pictures, and computer graphics. This was not possible with conventional holograms made by irradiating laser to modeling objects.

SDAD and Sony DADC which operates a global supply chain for the Entertainment and Information industries, aim to build a world class hologram manufacturing and sales business. In the future, SDAD will also explore the application of Lippmann holograms with individually distinct identification codes, which can store animation and motion picture, for advertising and marketing.

In addition to developing and mass producing Lippmann holograms with individually distinct identification codes, SDAD also envisions launching a new business whereby it will operate an authentication server via the internet, for CRM (Customer Relationship Management) and 'trace-and-track' services which utilize the individually assigned code on the holograms. SDAD will eventually introduce the Lippmann holograms with individually distinct identification codes as authentication stickers for Sony products. It will deliver sample holograms to product manufacturers in May 2010.

Lippmann holograms are used in order to protect IP. An optical interference fringe is formed by refractive index modulation in the special photo-sensitive material. When white-light is illuminated onto the photo-sensitive material, a holographic image appears through a diffractive phenomenon. Such conventional Lippmann holograms were mass-produced by contact copy in which the master forms of these holograms were optically replicated. This conventional method allows for the simple mass production of identical holograms, but does not allow for the mass production of holograms containing individually variable information. Sony has added an extra layer of protection by adding individually distinct identification codes in Lippmann holograms. The company claims that these are are extremely resistant to counterfeiting and forgery, and are most suitable for credit cards, smart IC cards and authentication stickers. SDAD plans to mass produce Lippmann holograms with up to 21 encrypted digits in a single hologram.

SDAD will use master-forms of holograms which are made by holographic stereogram technology with digital image processing which records more than one hundred images onto a single hologram sheet. Therefore it can store flying logos (three-dimensional computer graphics) and moving animation.

Lippmann holograms can be applied as advertising and marketing tools because it can display photographic images, pictures, and computer graphics. This was not possible with conventional holograms made by irradiating laser to modeling objects.

SDAD and Sony DADC which operates a global supply chain for the Entertainment and Information industries, aim to build a world class hologram manufacturing and sales business. In the future, SDAD will also explore the application of Lippmann holograms with individually distinct identification codes, which can store animation and motion picture, for advertising and marketing.

In addition to developing and mass producing Lippmann holograms with individually distinct identification codes, SDAD also envisions launching a new business whereby it will operate an authentication server via the internet, for CRM (Customer Relationship Management) and 'trace-and-track' services which utilize the individually assigned code on the holograms. SDAD will eventually introduce the Lippmann holograms with individually distinct identification codes as authentication stickers for Sony products. It will deliver sample holograms to product manufacturers in May 2010.