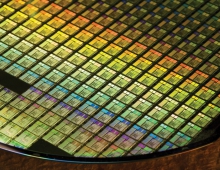

UMC Advances Its High-k/Metal-Gate Process Solution

UMC today announced a significant milestone for its high-k/metal-gate (HK/MG) technology with validation of the process through 45nm SRAM product yield.

This achievement is a first key-step in demonstrating technology performance and process reliability for HK/MG technology, which will be used for UMC?s next generation 32/28nm process.

"UMC is making steady progress in bringing our HK/MG process towards 32/28nm pilot production so that our customers can benefit from the performance advantages of this technology," said Mr. S.C. Chien, vice president of Advanced Technology Development at UMC. "Despite the global economic uncertainties, UMC continues to move full speed ahead with our advanced technology R&D efforts. With our recent achievement of working 28nm SRAM, coupled with this latest HK/MG process material validation, we are well positioned to offer customers a strong technology platform solution when our 32/28nm technology becomes available in 2010."

In October 2008, UMC produced the foundry industry?s first 28nm SRAM chips based on its low-leakage (LL) process, which utilized advanced double-patterning immersion lithography and strained silicon technology. UMC?s dual approach for its 32/28nm technology addresses different market applications. The foundry uses conventional silicon gate/silicon-oxy-nitride gate oxide technology for its LL process, which is ideal for portable applications such as mobile phone ICs, while the HK/MG stack is primarily aimed at speed-intensive products such as graphic, application processor, and high-speed communication ICs. The HK/MG option can also be customized for 32/28nm low power applications to address individual requirements.

"UMC is making steady progress in bringing our HK/MG process towards 32/28nm pilot production so that our customers can benefit from the performance advantages of this technology," said Mr. S.C. Chien, vice president of Advanced Technology Development at UMC. "Despite the global economic uncertainties, UMC continues to move full speed ahead with our advanced technology R&D efforts. With our recent achievement of working 28nm SRAM, coupled with this latest HK/MG process material validation, we are well positioned to offer customers a strong technology platform solution when our 32/28nm technology becomes available in 2010."

In October 2008, UMC produced the foundry industry?s first 28nm SRAM chips based on its low-leakage (LL) process, which utilized advanced double-patterning immersion lithography and strained silicon technology. UMC?s dual approach for its 32/28nm technology addresses different market applications. The foundry uses conventional silicon gate/silicon-oxy-nitride gate oxide technology for its LL process, which is ideal for portable applications such as mobile phone ICs, while the HK/MG stack is primarily aimed at speed-intensive products such as graphic, application processor, and high-speed communication ICs. The HK/MG option can also be customized for 32/28nm low power applications to address individual requirements.