Fujitsu Details Advanced 45nm Technology for Logic Chips

Fujitsu today announced their development of a platform technology for 45 nanometer (45nm) generation LSI logic chips, which combines technologies for low power consumption and high-performance interconnect.

Fujitsu said that compared to previous 45nm technologies on record, the new platform reduces the leakage current that occurs when current is wasted in wait states to one-fifth that of previous levels and reduces interconnect-induced lag times by approximately 14%. The new technology will enable Fujitsu to offer LSI logic chips that feature even higher speeds, smaller size and lower power consumption than currently available.

Details of the new technology were presented at the 2007 Symposium on VLSI Technology.

In order to heighten integration levels of LSIs, with each new generation of devices, there is a need to shorten the gate length of each transistor and make the spaces between interconnects narrower. In addition, to achieve high speeds there is a need to minimize the time lag from interconnects between the hundreds of millions of individual transistors within the LSI chip.

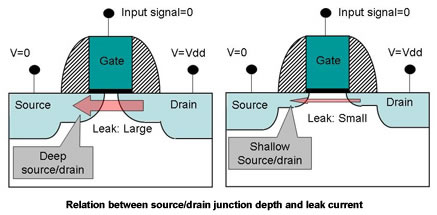

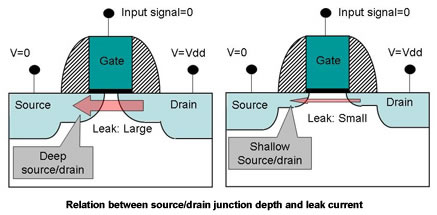

When a the gate length of a transistor is shortened, a problem that exists is increased power consumption attributable to increased leakage current between the transistor's source and drain when no signal voltage is applied at the gate - for example, when a mobile phone is on standby mode awaiting calls and no operation processing is underway.

For the 45nm generation, both the width of interconnects and the spaces between interconnects, are at the smallest 65nm. In addition to an increase of interconnect resistance due to miniaturization, if the insulating layer's dielectric constant stays the same as the previous generation, interconnect capacitance will increase, thereby resulting in increased interconnect lag and thus necessitating a material with lower dielectric constant.

Fujitsu researchers found that forming shallower source and drain regions is an effective way to reduce leakage current.

However, simply making them shallower also increases resistance at the source and drain regions, thereby degrading transistor performance. To counteract this, Fujitsu researchers developed a new annealing technology called millisecond annealing (MSA). Compared to previous annealing, Fujitsu's millisecond annealing technology uses higher temperatures thus enabling reduction of resistance, and because the annealing time is brief it possible to form shallow sources and drain regions and thereby reduce leakage current.

Fujitsu researchers also used nano-clustering silica (NCS), which has a dielectric constant (k) of 2.25 - the lowest of any insulating film reported to date - in a lower interconnect region suitable for the smallest interconnect spaces.

NCS is an insulating material pocked with miniscule holes, enabling both a low dielectric value and high mechanical strength simultaneously. Fujitsu introduced NCS on a partial basis beginning with the 65nm generation. However, for the 45nm generation, the company is using NCS not just within a given interconnect layer but also between different layers to further reduce interconnect capacitance.

"The new technique is highly effective in limiting transistor resistance, reducing leakage current to one-fifth that of previous levels, thereby enabling advantages such as extending mobile phone maximum standby (wait) time up to five-fold," said Fujitsu in a statement.

In addition, by utilizing high-performance interconnect technology Fujitsu was able to achieve a 14% reduction in interconnect lag time in comparison to standard 45nm generation interconnect technologies in the International Technology Roadmap for Semiconductors.

Fujitsu is targeting 2008 to incorporate these technologies into LSIs that are suited for mobile devices.

Details of the new technology were presented at the 2007 Symposium on VLSI Technology.

In order to heighten integration levels of LSIs, with each new generation of devices, there is a need to shorten the gate length of each transistor and make the spaces between interconnects narrower. In addition, to achieve high speeds there is a need to minimize the time lag from interconnects between the hundreds of millions of individual transistors within the LSI chip.

When a the gate length of a transistor is shortened, a problem that exists is increased power consumption attributable to increased leakage current between the transistor's source and drain when no signal voltage is applied at the gate - for example, when a mobile phone is on standby mode awaiting calls and no operation processing is underway.

For the 45nm generation, both the width of interconnects and the spaces between interconnects, are at the smallest 65nm. In addition to an increase of interconnect resistance due to miniaturization, if the insulating layer's dielectric constant stays the same as the previous generation, interconnect capacitance will increase, thereby resulting in increased interconnect lag and thus necessitating a material with lower dielectric constant.

Fujitsu researchers found that forming shallower source and drain regions is an effective way to reduce leakage current.

However, simply making them shallower also increases resistance at the source and drain regions, thereby degrading transistor performance. To counteract this, Fujitsu researchers developed a new annealing technology called millisecond annealing (MSA). Compared to previous annealing, Fujitsu's millisecond annealing technology uses higher temperatures thus enabling reduction of resistance, and because the annealing time is brief it possible to form shallow sources and drain regions and thereby reduce leakage current.

Fujitsu researchers also used nano-clustering silica (NCS), which has a dielectric constant (k) of 2.25 - the lowest of any insulating film reported to date - in a lower interconnect region suitable for the smallest interconnect spaces.

NCS is an insulating material pocked with miniscule holes, enabling both a low dielectric value and high mechanical strength simultaneously. Fujitsu introduced NCS on a partial basis beginning with the 65nm generation. However, for the 45nm generation, the company is using NCS not just within a given interconnect layer but also between different layers to further reduce interconnect capacitance.

"The new technique is highly effective in limiting transistor resistance, reducing leakage current to one-fifth that of previous levels, thereby enabling advantages such as extending mobile phone maximum standby (wait) time up to five-fold," said Fujitsu in a statement.

In addition, by utilizing high-performance interconnect technology Fujitsu was able to achieve a 14% reduction in interconnect lag time in comparison to standard 45nm generation interconnect technologies in the International Technology Roadmap for Semiconductors.

Fujitsu is targeting 2008 to incorporate these technologies into LSIs that are suited for mobile devices.