Western Digital Demonstrates World's First Microwave-assisted Magnetic Recording (MAMR) HDD

Western Digital today announced an innovation for delivering ultra-high capacity hard disk drives (HDDs). The company demonstrated the world's first microwave-assisted magnetic recording (MAMR) HDD.

WD held an event at its eadquarters in Silicon Valley, with speakers to include the inventor of MAMR technology, Professor Jimmy Zhu from Carnegie Mellon University. The company also showcased advancements in micro actuation and Damascene recording head technology. Western Digital expects to begin shipping ultra-high capacity MAMR HDDs in 2019 for use in data centers that support Big Data applications across a full range of industries.

"Our ground-breaking advancement in MAMR technology will enable Western Digital to address the future of high capacity storage by redefining the density potential of HDDs and introduce a new class of highly reliable, 'ultra-high capacity' drives," said said Mike Cordano, president and chief operating officer at Western Digital.

MAMR is one of two energy-assisted technologies that Western Digital has been developing for years. The company says it recently innovated a breakthrough in material and process that provides the required reliable and predictable performance, as well as the manufacturability to accelerate areal density and cost improvements to an estimated average of 15 percent per year. WD says that developments in the other energy-assisted technology, such as the heat-assisted magnetic recording (HAMR), present new material science and reliability challenges that are not a factor in MAMR. "Only MAMR demonstrates the reliability and cost profile that meets the demands of data center operators," WD added.

Obviously, it is Western Digital's assessment that HAMR drives will not be commercially viable in the near term. The company will continue to make appropriate investments in the technology, consistent with its product investment strategy, anticipating new innovations. At the same time, WD has chosen to introduce a more cost-effective, more reliable solution based on microwave-assisted magnetic recording (MAMR) technology.

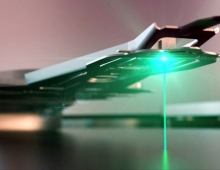

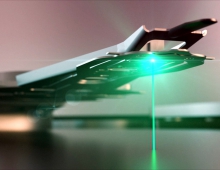

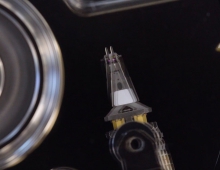

MAMR technology uses a microwave field generated from a spin torque oscillator (STO). In this method, the STO located near the write pole of the head generates an alternating current (AC) field that allows data to be written to the perpendicular magnetic media at a lower magnetic field. The magnetic grains on disk are similar to spinning gyroscopes that are stable in either an up or down direction in the absence of an external field. When a sufficient magnetic field is applied in the opposite direction of the magnetic moment, the polarity flips in the direction of the applied field. Applying an additional gigahertz AC field from the STO can deliver that magnetic moment and flip the magnets more quickly, and at a lower magnetic field. While the theory behind MAMR has been known in the industry, and in academia for many years, producing a manufacture-able head that demonstrates the MAMR effect, was elusive.

From internal testing, MAMR technology is demonstrating higher gains than the best PMR heads currently available, and shows promising areal density growth. Lifetime reliability tests show that the median time to failure of MAMR heads is one hundred times better than HAMR heads. Additionally, reliability tests over a population of heads show that the write lifetime hours demonstrated for 99.99% of MAMR heads is several orders better than the write lifetime hours for 99.99% of HAMR heads.

Academic studies show that MAMR also has the capability to extend areal density gains to 4Tb per square inch (in2), and beyond, delivering significantly better gains than drives shipping today (SMR drive gains equal 1,300Gb/in2, while PMR drive gains equal 1,100Gb/in2).

Western Digital is investing in the advanced Damascene process, advanced micro actuation, and continued research in MAMR technology to extend track densities to over one million tracks per inch. With sustained improvements in recording density, MAMR promises to enable hard drives with 40TB of capacity and beyond by 2025, and continued expansion beyond that timeframe.

Western Digital's MAMR technology builds upon a number of other innovations from the company. In addition to HelioSeal helium-filled drive technology, MAMR also builds upon the company's micro actuation and recording head manufacturing technologies. Western Digital's advanced micro actuation technology for data center applications enables hard drives to accurately position magnetic heads for writing and reading at ultra-high densities. The company's head manufacturing operations utilize Damascene processing to manufacture heads with the precise tolerances and complex structures required for reliable and cost-effective recording at ultra-high densities. The Damascene process also provides the capability to embed the spin torque oscillator that enables the manufacturing of MAMR heads.

Western Digital feels that the data storage industry can now benefit from increased capacities with MAMR technology and will productize MAMR-based drives for availability in 2019.