DVD Technical Guide

5. Features of the DVD Physical Specification

Review Pages

2. Concepts and Structure of the DVD Format

3. The Future of DVD

4. Design Concept of the Physical Specification

5. Features of the DVD Physical Specification

6. The DVD Data Format

7. Read-Only Disc File Format

8. Video Format

9. Video Format - Page 2

10. Video Format - Page 3

11. Audio Format

12. Audio Format - Page 2

13. Audio Format - Page 3

14. Audio Format - Page 4

15. Audio Format - Page 5

16. DVD-R and DVD-RW

17. DVD-R and DVD-RW - Page 2

18. DVD-R and DVD-RW - Page 3

19. DVD-R and DVD-RW - Page 4

20. DVD-RAM

21. DVD-RAM - Page 2

22. DVD-RAM - Page 3

23. DVD-RAM - Page 4

Chapter 2 - Physical Format of Read-Only Discs

2.2 Features of the DVD Physical Specification

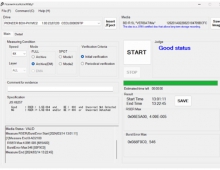

2.2.1 Standard evaluation specifications

The table below shows a comparison of the basic specifications used in evaluating specification compliance for CD and DVD discs. As shown in the table, the NA value is considerably larger for DVD. Since these are standard evaluation specifications, the limits on variability are quite tight. Further, there are specifications for items which were not specified for CDs, such as servo characteristics and transfer characteristics of playback system elements like laser diodes and waveform equalizers. Since the recording density is higher in DVD, the shortest mark is shifted toward the high range of the MTF low-pass optical system transfer function. The DVD has an MTF of 68%, compared with 50% for a CD system. As a result, the system requires waveform equalization for demodulation. Because the waveform equalization function changes the error rate and jitter value, the playback system transfer characteristics are set, including the waveform equalization function of a standard test device. As a result, it is possible to indirectlyspecify the performance of the LBR master recording device. The DVD specification also defines standard servo characteristics. These are closely related to the disc mechanical characteristics, which will be described later. For CDs, disc surface deviation and radial deviation are specified as accelerations. However, it is difficult to measure acceleration and produce repeatable measurement values. This issue was investigated during the work on the ISO 3.5" disc. The result was to specify standard servo characteristics and to specify disc mechanical properties with the residual error after servo compression. The key feature of this method is the ability to generate repeatability of data. The DVD specification uses the same method. In specifying servo characteristics, open-loop specifications were avoided, as they are subject to wide variation; instead, closed-loop parameters were specified. Please refer to the DVD specification for playback system transfer characteristics and servo characteristics.

Further, the detector size is specified for measurement of dual layer discs. This is done with the intent of limiting the amount of inter-layer crosstalk. Care must be taken, as use of a larger detector will introduce obstacles to other measurements, particularly to reflectivity measurements, due to inter-layer crosstalk. As a side note, detectors usually utilize PIN photo diodes, and electrons excited by light entering from other than the detector portion can result in a considerable DC offset. Therefore, during measurement the detector should be shielded from stray light, or grounded to bleed off the stray electrons.

| Comparison of standard evaluation specifications | ||

|---|---|---|

DVD |

CD | |

| wavelength | 650 |

780 |

| NA | 0.60 |

0.45 |

| polarization | circular | - |

| light intensity at the rim (of the pupil of the abjective lens) |

RAD:60-70% TAN:90% or more |

50% or less |

| surface aberration | 0.033 |

0.07 |

| laser diode noise | -134 dB/Hz or less | - |

| measuring scanning velosity | 3.49 3.84 |

- |

| disc clamping force | 2.0 |

1-2N |

| circuit characteristics | standard servo, equalizer, PLL, CLV servo, slicer characteristics |

- |

2.2.2 Jitter specification

The DVD specification includes a standard for jitter, which is not found in the CD specification. The logical format specifies disc mechanical and optical characteristics, but specifications for sources of degradation, like inter-symbol interference introduced in the disc cutting step, are not included in the current CD specification. There are also items which cannot be expressed by parameters listed in the current CD specification, such as degradation introduced by the mastering machine or unevenness in pit replication.

These effects can't be ignored in DVDs with their higher recording density, and thus it is necessary to specify such factors. There was an error rate specification in the CD specification, but this is impossible to measure unless there are defects or degradation due to the playback device.

These effects can't be ignored in DVDs with their higher recording density, and thus it is necessary to specify such factors. There was an error rate specification in the CD specification, but this is impossible to measure unless there are defects or degradation due to the playback device.

The disc specification for Pioneer's ![]() Karaoke System specified an error rate using a tilted pickup, but this was a difficult measurement to make, and certainly not efficient. In the DVD specification it was decided to add a jitter specification, as jitter is a parameter where degradation can be measured numerically. Jitter is measured in the absence of tilt, which is an ideal disc specification, but it isn't practical to compensate for tilt at all points. Since the effect of jitter due to the varying component of surface tilt is small, it was decided to measure across one full revolution and measure the average value of tilt variation. As a result, it is only necessary to compensate for the average radial tilt when taking measurements.

Karaoke System specified an error rate using a tilted pickup, but this was a difficult measurement to make, and certainly not efficient. In the DVD specification it was decided to add a jitter specification, as jitter is a parameter where degradation can be measured numerically. Jitter is measured in the absence of tilt, which is an ideal disc specification, but it isn't practical to compensate for tilt at all points. Since the effect of jitter due to the varying component of surface tilt is small, it was decided to measure across one full revolution and measure the average value of tilt variation. As a result, it is only necessary to compensate for the average radial tilt when taking measurements.

2.2.3 Tilt specification

The disc tilt limit is

The disc tilt limit is ![]() 0.8

0.8![]() in the radial direction, and

in the radial direction, and ![]() 0.3

0.3![]() in the tangential direction. The specification for the radial direction is larger in consideration of the fact that it's easy for the disc to curve into a bowl shape.

in the tangential direction. The specification for the radial direction is larger in consideration of the fact that it's easy for the disc to curve into a bowl shape.

Note that the tilt angle defined by the specification is not just the physical angle of inclination, but rather the angle between incident and reflected light (![]() ), measured optically.

), measured optically.

Of course, the specification defines characteristics of discs when shipped from the factory; but it also requires guaranteed disc characteristics after being subject to conditions in the marketplace. However, there are a wide variety of environmental conditions in the marketplace, making that very difficult to specify. Therefore, an Informative Annex to the DVD specification describes the minimum environmental tests. Care must be taken, for example, not to use adhesives that will degrade at the specified high temperatures.

As a side note, there have been reports of degradation due to disc tilt resulting from the use of improper cases and packing.

For CDs, the reflectivity specification is for a disc with a reflective surface only, with no information recorded on the disc; practically speaking, this is very difficult to test. The DVD specification takes into account the player design, and specifies reflectivity in terms of the maximum playback signal level I14HThis is very easy to measure. In this case there are effects from disc birefringence, so the specification defines values for both polarizing and non-polarizing optical systems.

There are actually two sets of reflectivity specifications, as reflectivity differs between single layer and dual layer discs. For the polarizing optical system, the specified values are 45-85% for single layer discs, and 18-30% for dual layer discs. However, note that there are specifications for I14Hvariations across the surface and around a revolution, for the purpose of limiting variation in servo gain.

Further note that the minimum I14Hreflectivity value for DVD-RAM discs is about 10%. For more detailed information, please refer to the DVD-RAM specification. Ordinarily, the detection of whether or not a disc is loaded in a tray is done by attempting to focus on the disc. This means that the focussing mechanism must handle discs with a reflectivity of only 10%.

The DVD specification adds an item for a crosstalk signal which expresses the contrast when cutting across a track, and which is used in pulling in of tracking and disc access. Since the track pitch is narrow and crosstalk noise is high, the crosstalk signal is specified to be measured after running through a 30 kHz low-pass filter.

The table below shows the difference in some other parameters between the CD and DVD specifications. When playing video from a DVD, the disc spins at a rate which provides a linear speed of 3.49 m/s. (The linear speed of a CD is 1.2 to 1.4 m/s.) If disc warpage and eccentricity is the same for a DVD disc as for a CD, it would require a high bandwidth actuator to allow the pickup to follow the disc movement. This would raise the further complication of increased heat generation. This must be avoided to enable portable applications, and so the DVD specifications for disc eccentricity and surface deviation were made more strict than for CDs. Note that for dual layer discs the layer closest to the pickup is aligned during the clamping process. Therefore, the maximum eccentricity value is large, considering the de-center that can occur during bonding with the other bonded layer.

| DVD | CD |

|---|---|

| track pitch0.74 0.74 |

1.6 |

| eccentricity (radial runout)100 |

140 |

| warpage (surface deviation) |

Since the DVD medium is a bonded disc, there must be a specification for the maximum allowable de-center in the bond. Since the specification includes variation in mass, a specification item for dynamic balance was created.

Further, so that the back side of the tapered cone used during clamping doesn't contact the inside diameter of the disc, and so that no problems occur if a DVD is accidentally loaded into a CD player, the inside diameter is specified to not be less than 15.0 mm when viewed through both surfaces.

To maintain bonding strength, the maximum value of the depression on the inside of the clamping area was changed to 0.1 mm, from the CD value of 0.2 mm. And, considering LD and DVD compatible players, the maximum value of the stack ring thickness variability area protrusion on the outside of the clamping area was changed to 0.25 mm, from the CD value of 0.4 mm.

The program start radius of a CD is 25 mm. This was reduced to 24 mm for DVD to increase the disc capacity. The lead-in start radius is 22.6 mm. The maximum radius of the program region is 58 mm, followed by a lead-out of at least 0.5 mm width. Further, in order to insure that there is some region with program recorded, the minimum value of the outer radius of the information region is required to be 35 mm.

Review Pages

2. Concepts and Structure of the DVD Format

3. The Future of DVD

4. Design Concept of the Physical Specification

5. Features of the DVD Physical Specification

6. The DVD Data Format

7. Read-Only Disc File Format

8. Video Format

9. Video Format - Page 2

10. Video Format - Page 3

11. Audio Format

12. Audio Format - Page 2

13. Audio Format - Page 3

14. Audio Format - Page 4

15. Audio Format - Page 5

16. DVD-R and DVD-RW

17. DVD-R and DVD-RW - Page 2

18. DVD-R and DVD-RW - Page 3

19. DVD-R and DVD-RW - Page 4

20. DVD-RAM

21. DVD-RAM - Page 2

22. DVD-RAM - Page 3

23. DVD-RAM - Page 4