Mitsubishi Chemical and Pioneer Concluded Business and Capital Alliance

Mitsubishi Chemical has decided to enter the OLED lighting business, aiming to begin full-scale mass production and launch of illumination appliances in 2011. Target sales for the OLED lighting business are 30 billion Japanese yen for 2015, and 100 billion Japanese yen for 2020.

Mitsubishi Chemical has decided to enter the OLED lighting business, aiming to begin full-scale mass production and launch of illumination appliances in 2011. Target sales for the OLED lighting business are 30 billion Japanese yen for 2015, and 100 billion Japanese yen for 2020.

With this business move, Mitsubishi Chemical will use OLED lighting panels supplied by Pioneer. It is also looking into performing joint research on printable OLED lighting development, as well as their commercialization.

Also, in order to strengthen the strategic partnership between the two companies, Pioneer will issue Mitsubishi Chemical about 600 million Japanese yen in new stock through third-party allotment. Both companies are currently performing joint research on OLED lighting panels that use printable hole injecting material (HIM) and new emitting materials . In line with its goal to start early stage mass production and marketing of new printable emitting materials, Mitsubishi Chemical is moving on with research and development, as well as looking into the commercialization of printable OLED lighting.

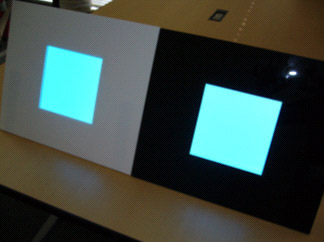

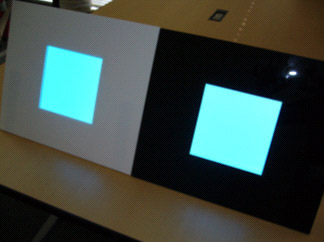

OLED lighting does not create a spot of light or a strip of light like electric bulbs and fluorescent lights. Brightness and color can be freely controlled (dimness/tone), lighting can be made transparent (can see through to the other side like a glass window), and it can be made flexible (light surface can be flat or curved, shapes can be freely formed). Also, the fact that it does not use mercury and uses low amounts of energy makes it an environmental-friendly next-generation lighting medium.

Currently, OLED lighting panels are commonly created through a vapor deposition process, which makes it difficult to mass-produce no-defects, large, uniform surfaces. However, Mitsubishi Chemical's printable materials realize the mass production of the world's largest class of lighting area, about 14cm square, with Pioneer's commercial lines.

Mitsubishi Chemical will be supplied OLED lighting panels by Pioneer, then launch illumination appliances that make use of the unique benefits of OLED across Verbatim's worldwide sales network starting in 2011.

Also in relation to Mitsubishi Chemical's OLED illumination appliances, the company plans to display the world's first dimmable/tone adjustable prototype this year from April 11 - 16 in Frankfurt, Germany at Light+Building 2010, the world's leading trade fair for architecture and technology.

Both companies are continuing their joint research on OLED lighting panels not only printable HIM, but also new printable emitting materials. These new printable materials enables an emitting layer to be low-cost application process that has achieved a characteristic illumination life time (the time it takes for the brightness to reduce to 70% of its starting value) of 10,000 hours in the laboratory.

With this business move, Mitsubishi Chemical will use OLED lighting panels supplied by Pioneer. It is also looking into performing joint research on printable OLED lighting development, as well as their commercialization.

Also, in order to strengthen the strategic partnership between the two companies, Pioneer will issue Mitsubishi Chemical about 600 million Japanese yen in new stock through third-party allotment. Both companies are currently performing joint research on OLED lighting panels that use printable hole injecting material (HIM) and new emitting materials . In line with its goal to start early stage mass production and marketing of new printable emitting materials, Mitsubishi Chemical is moving on with research and development, as well as looking into the commercialization of printable OLED lighting.

OLED lighting does not create a spot of light or a strip of light like electric bulbs and fluorescent lights. Brightness and color can be freely controlled (dimness/tone), lighting can be made transparent (can see through to the other side like a glass window), and it can be made flexible (light surface can be flat or curved, shapes can be freely formed). Also, the fact that it does not use mercury and uses low amounts of energy makes it an environmental-friendly next-generation lighting medium.

Currently, OLED lighting panels are commonly created through a vapor deposition process, which makes it difficult to mass-produce no-defects, large, uniform surfaces. However, Mitsubishi Chemical's printable materials realize the mass production of the world's largest class of lighting area, about 14cm square, with Pioneer's commercial lines.

Mitsubishi Chemical will be supplied OLED lighting panels by Pioneer, then launch illumination appliances that make use of the unique benefits of OLED across Verbatim's worldwide sales network starting in 2011.

Also in relation to Mitsubishi Chemical's OLED illumination appliances, the company plans to display the world's first dimmable/tone adjustable prototype this year from April 11 - 16 in Frankfurt, Germany at Light+Building 2010, the world's leading trade fair for architecture and technology.

Both companies are continuing their joint research on OLED lighting panels not only printable HIM, but also new printable emitting materials. These new printable materials enables an emitting layer to be low-cost application process that has achieved a characteristic illumination life time (the time it takes for the brightness to reduce to 70% of its starting value) of 10,000 hours in the laboratory.