Showa Denko To Produce Next Generation SMR and HAMR Hard Disk Media In 2015

Japanese chemical engineering firm Showa Denko K.K (SDK) will promote technical development to prepare for the volume production of higher-capacity, next generation Hard Disk media in the next couple of years.

Demand for hard disk drives (HDDs) is decreasing due to the shift in applications from PCs to servers. In the short term, this trend has stalled the demand for HD media. However, the company expects demand for HD media to increase in a medium term, reflecting the growth in server applications that require a larger number of HD media per HDD.

To meet the growing demand for HD media for server applications, SDK will increase productivity by fully taking advantage of its strengths as an integrated producer of aluminum substrates and Hard Disk media. SDK already makes 2.5-inch PMR HDDs with a recording density of 670GB/platter, and will prepare for the volume production of higher-capacity HD media based on shingled magnetic recording (SMR) and thermally assisted magnetic recording (TAMR) technologies in the second halg of 2014 and towards 2015. The company estimates that SMR media will hold 750GB/platter while TAMR will furhter boost areal data density to deliver 1TB/platter.

SMR is critical for continued improvement in areal density (the amount of data that can be stored on a single disk). The SMR generation of storage technology is expected to power gains of up to 25 percent or 1.25TB per disk. A fundamental change to the architecture of the media, SMR technology rearranges the way data is stored on a disk by overlapping tracks - similar to shingles on a roof - thereby, increasing track density and improving aerial density.

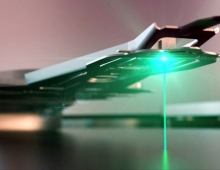

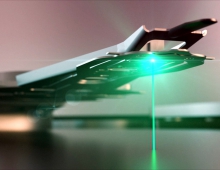

Thermally/Heat Assisted Magnetic Recording technology (HAMR or TAMR) is a technology that magnetically records data on high-stability media using laser thermal assistance to first heat the material. HAMR takes advantage of high-stability magnetic compounds such as iron platinum alloy. These materials can store single bits in a much smaller area without being limited by the same superparamagnetic effect that limits the current technology used in hard disk storage. The only catch being that they must be heated to apply the changes in magnetic orientation. HAMR was developed by Fujitsu in 2006.

HAMR's challenges include solving a range of engineering challenges such as how to integrate laser diodes and recording heads. Patterned media proponents have yet to demonstrate ways to cover a full disk with tiny magnetic dots in a way that can be mass produced.

Seagate plans to evolve to SMR and later HAMR technology, as its roadmap does not include the helium technology supported by Western Digital.

For now, Seagate is expected to continue its developments on the current standard PMR technology, with the next quarter launchof a new 3.5-inch HDD at 5TB with five 1TB platters.

Its highest capacity desktop drive is currently the 6Gb SATA ST4000DM000 at 4TB with fours disks and height heads. WD (WD Re or WD4000FYYZ) and HGST (Ultrastar 7K4000) also have 4TB 3.5-inch models, as well as Toshiba (MG03ACA/MG03SCA and MG03ACAY/MG03SCP).

WD's subsidiary HGST is already producing the Ultrastar He6, filled with helium, reaching the worldwide record of 6TB with seven disks packed in the same 3.5-inch form factor standard.

To meet the growing demand for HD media for server applications, SDK will increase productivity by fully taking advantage of its strengths as an integrated producer of aluminum substrates and Hard Disk media. SDK already makes 2.5-inch PMR HDDs with a recording density of 670GB/platter, and will prepare for the volume production of higher-capacity HD media based on shingled magnetic recording (SMR) and thermally assisted magnetic recording (TAMR) technologies in the second halg of 2014 and towards 2015. The company estimates that SMR media will hold 750GB/platter while TAMR will furhter boost areal data density to deliver 1TB/platter.

SMR is critical for continued improvement in areal density (the amount of data that can be stored on a single disk). The SMR generation of storage technology is expected to power gains of up to 25 percent or 1.25TB per disk. A fundamental change to the architecture of the media, SMR technology rearranges the way data is stored on a disk by overlapping tracks - similar to shingles on a roof - thereby, increasing track density and improving aerial density.

Thermally/Heat Assisted Magnetic Recording technology (HAMR or TAMR) is a technology that magnetically records data on high-stability media using laser thermal assistance to first heat the material. HAMR takes advantage of high-stability magnetic compounds such as iron platinum alloy. These materials can store single bits in a much smaller area without being limited by the same superparamagnetic effect that limits the current technology used in hard disk storage. The only catch being that they must be heated to apply the changes in magnetic orientation. HAMR was developed by Fujitsu in 2006.

HAMR's challenges include solving a range of engineering challenges such as how to integrate laser diodes and recording heads. Patterned media proponents have yet to demonstrate ways to cover a full disk with tiny magnetic dots in a way that can be mass produced.

Seagate plans to evolve to SMR and later HAMR technology, as its roadmap does not include the helium technology supported by Western Digital.

For now, Seagate is expected to continue its developments on the current standard PMR technology, with the next quarter launchof a new 3.5-inch HDD at 5TB with five 1TB platters.

Its highest capacity desktop drive is currently the 6Gb SATA ST4000DM000 at 4TB with fours disks and height heads. WD (WD Re or WD4000FYYZ) and HGST (Ultrastar 7K4000) also have 4TB 3.5-inch models, as well as Toshiba (MG03ACA/MG03SCA and MG03ACAY/MG03SCP).

WD's subsidiary HGST is already producing the Ultrastar He6, filled with helium, reaching the worldwide record of 6TB with seven disks packed in the same 3.5-inch form factor standard.