TDK To Double The Recording Capacity Of Hard Disks

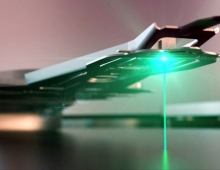

TDK Corp. said it has developed new technology that more than doubles the recording capacity of hard disk drives, using a heat-assisted magnetic recording head with a laser diode.

The new technology makes it easier to write data by adding heat to the disk platter using a laser. TDK has managed to include the laser diode into the the magnetic head of the HDD.

Magnetic recording media are discrete media each made of an aggregate of magnetic fine particles, each magnetic fine particle forming a single-domain structure. A single recording bit of a magnetic recording medium is composed of a plurality of magnetic fine particles. For improved recording density, it is necessary to reduce asperities at the borders between adjoining recording bits. To achieve this, the magnetic fine particles must be made smaller. However, making the magnetic fine particles smaller causes the problem that the thermal stability of magnetization of the magnetic fine particles decreases with decreasing volume of the magnetic fine particles. To solve this problem, it is effective to increase the anisotropic energy of the magnetic fine particles. However, increasing the anisotropic energy of the magnetic fine particles leads to an increase in coercivity of the magnetic recording medium, and this makes it difficult to perform data recording with existing magnetic heads.

To solve the problem, there has been proposed a technique so-called heat-assisted magnetic recording. This technique uses a magnetic recording medium having high coercivity. When recording data, a magnetic field and heat are simultaneously applied to the area of the magnetic recording medium where to record data, so that the area rises in temperature and drops in coercivity for data recording.

In heat-assisted magnetic recording, near-field light is typically used as a means for applying heat to the magnetic recording medium.

Here is how TDK describes the construction of this heat-assisted magnetic recording head:

A heat-assisted magnetic recording head includes a slider, and an edge-emitting laser diode that emits polarized light of TM mode. The laser diode is arranged so that its bottom surface faces the top surface of the slider. An electrode of the laser diode closer to the active layer is bonded to a conductive layer of the slider, whereby the laser diode is fixed to the slider. As viewed from above the laser diode, the bottom surface of the electrode of the laser diode includes a first area that a light propagation path of the laser diode overlies, and a second area. The top surface of the conductive layer is in contact only with the second area of the bottom surface of the electrode.

A 2.5-inch HDD featuring the new technology is expected to have a storage capacity of 1 terabyte per platter, more than double the currently available hard disks.

TDK plans to to mass produce hard disk drives with enlarged recording capacities in the end of 2012.

Magnetic recording media are discrete media each made of an aggregate of magnetic fine particles, each magnetic fine particle forming a single-domain structure. A single recording bit of a magnetic recording medium is composed of a plurality of magnetic fine particles. For improved recording density, it is necessary to reduce asperities at the borders between adjoining recording bits. To achieve this, the magnetic fine particles must be made smaller. However, making the magnetic fine particles smaller causes the problem that the thermal stability of magnetization of the magnetic fine particles decreases with decreasing volume of the magnetic fine particles. To solve this problem, it is effective to increase the anisotropic energy of the magnetic fine particles. However, increasing the anisotropic energy of the magnetic fine particles leads to an increase in coercivity of the magnetic recording medium, and this makes it difficult to perform data recording with existing magnetic heads.

To solve the problem, there has been proposed a technique so-called heat-assisted magnetic recording. This technique uses a magnetic recording medium having high coercivity. When recording data, a magnetic field and heat are simultaneously applied to the area of the magnetic recording medium where to record data, so that the area rises in temperature and drops in coercivity for data recording.

In heat-assisted magnetic recording, near-field light is typically used as a means for applying heat to the magnetic recording medium.

Here is how TDK describes the construction of this heat-assisted magnetic recording head:

A heat-assisted magnetic recording head includes a slider, and an edge-emitting laser diode that emits polarized light of TM mode. The laser diode is arranged so that its bottom surface faces the top surface of the slider. An electrode of the laser diode closer to the active layer is bonded to a conductive layer of the slider, whereby the laser diode is fixed to the slider. As viewed from above the laser diode, the bottom surface of the electrode of the laser diode includes a first area that a light propagation path of the laser diode overlies, and a second area. The top surface of the conductive layer is in contact only with the second area of the bottom surface of the electrode.

A 2.5-inch HDD featuring the new technology is expected to have a storage capacity of 1 terabyte per platter, more than double the currently available hard disks.

TDK plans to to mass produce hard disk drives with enlarged recording capacities in the end of 2012.